AAC Brick Production Line

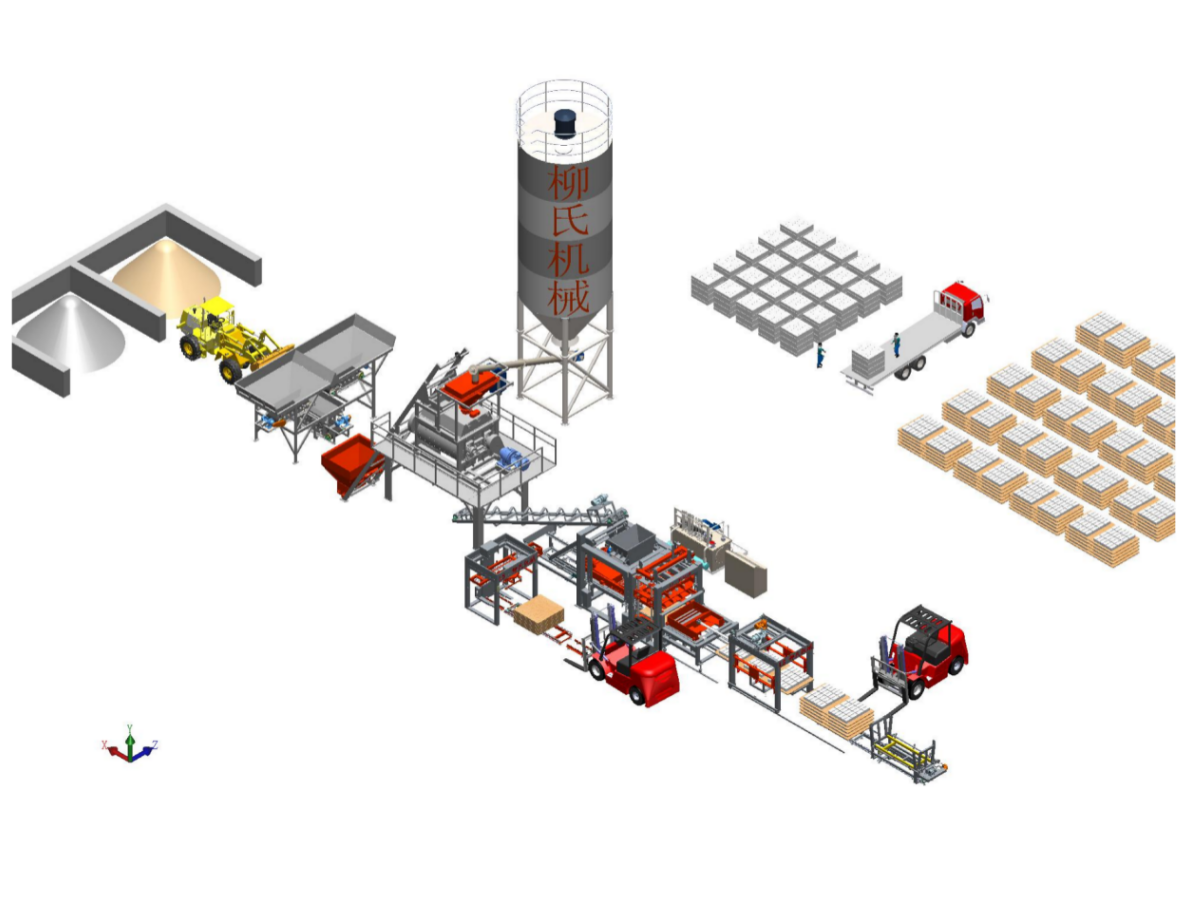

Quanzhou Liushi Machinery Co., Ltd., established in 2006, is a modern technology enterprise specializing in the research, development, manufacturing, sales, and service of brick-making machinery. Our AAC (Autoclaved Aerated Concrete) brick production line is designed to meet the demands of modern construction with high efficiency, reliability, and precision. We offer solutions for producing AAC blocks using different raw materials, including fly ash and sand, ensuring versatility and adaptability for various production needs.

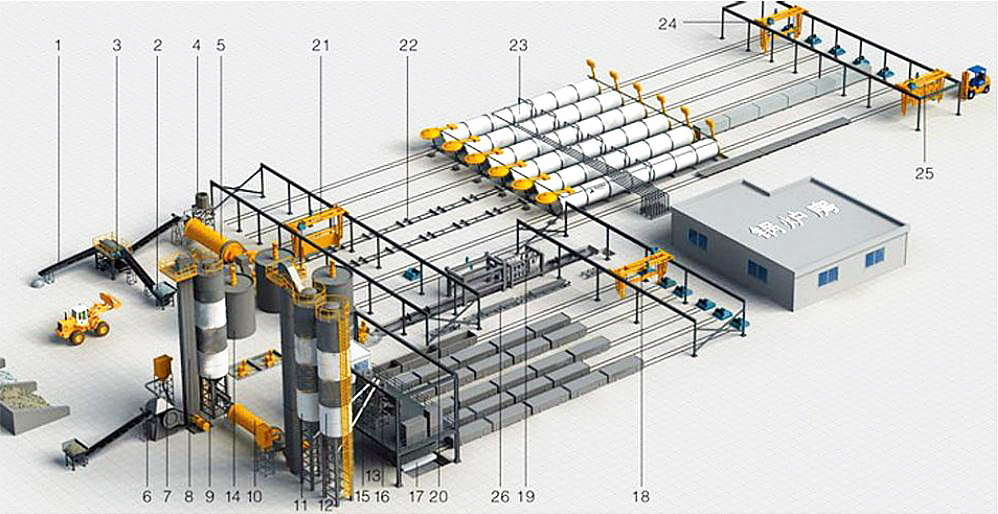

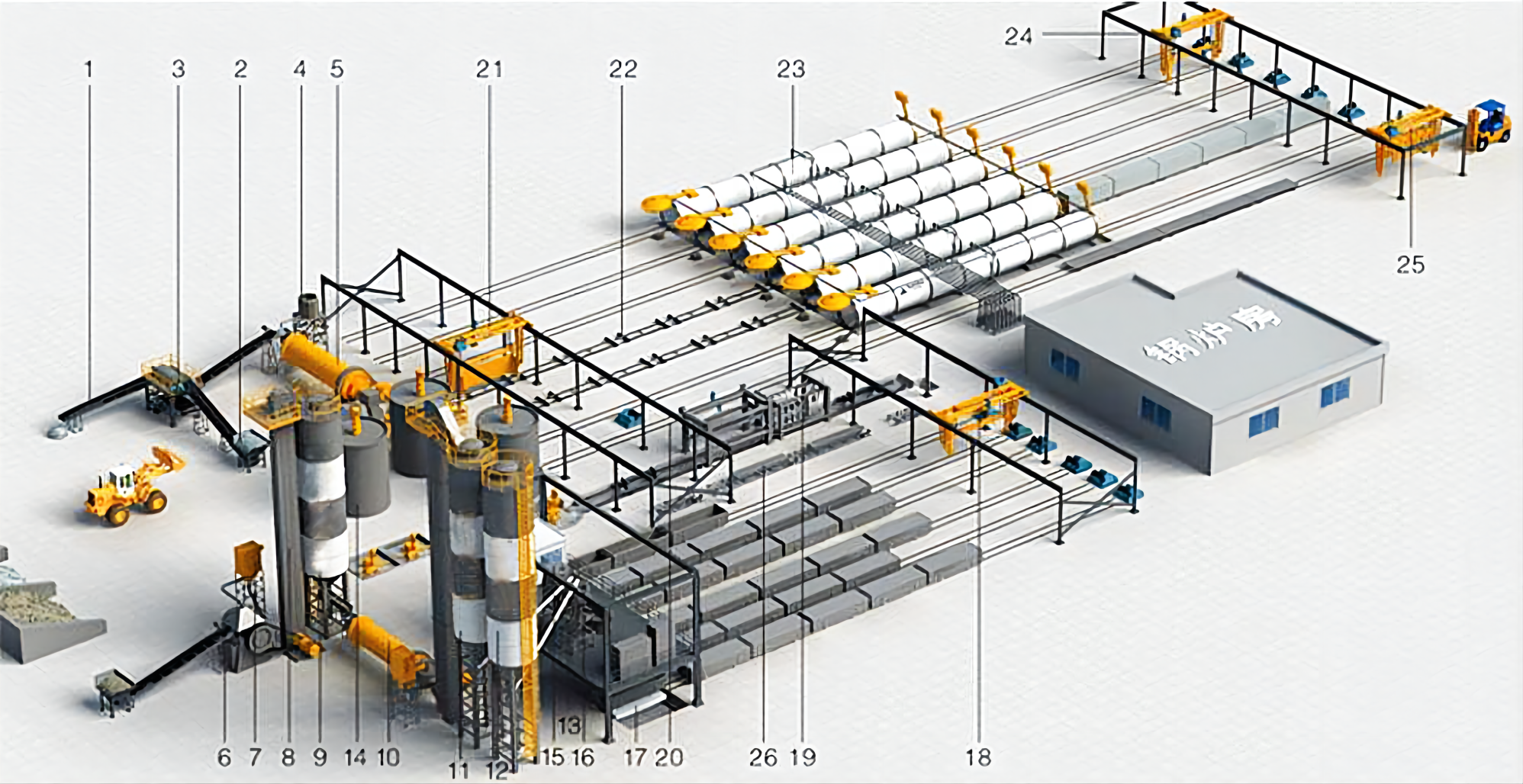

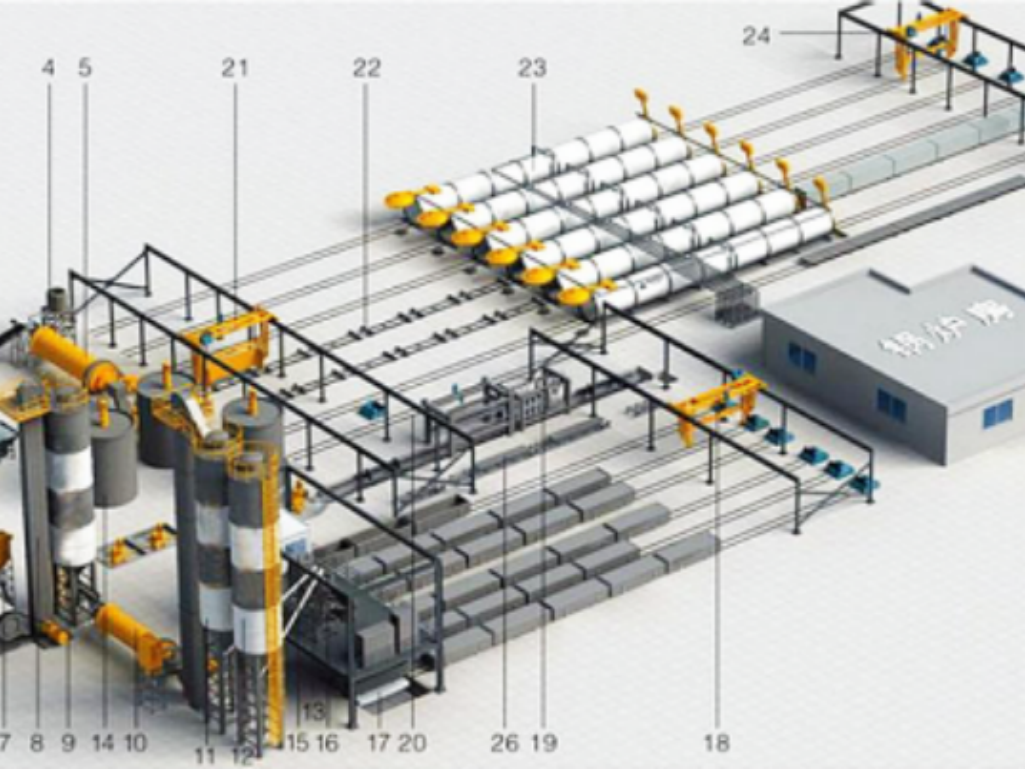

Components of the AAC Brick Production Line

- Belt Conveyor: Transports raw materials throughout the production line efficiently.

- Batcher: Accurately measures and dispenses raw materials for consistent quality.

- Roller Screen: Screens raw materials to remove impurities.

- Grinding Head Slurry Tank: Mixes and stores the slurry for the AAC blocks.

- Wet Ball Mill: Grinds raw materials to a fine consistency for better processing.

- Jaw Crusher: Crushes raw materials into smaller, manageable sizes.

- Deduster: Removes dust particles from the production process.

- Elevator: Lifts raw materials to different levels of the production line.

- Coarse Lime Bin: Stores coarse lime before further processing.

- Dry Ball Mill: Further grinds lime to a finer consistency.

- Fine Lime Bin: Stores finely ground lime.

- Cement Silo: Stores cement for the production process.

- Screw Conveyor: Transports powdered materials like cement and lime.

- Slurry Storage Tank: Stores mixed slurry for the production process.

- Slurry Measuring Tank: Measures the correct amount of slurry needed.

- Cement Measuring Tank: Measures the correct amount of cement needed.

- Ferry Vehicle: Transports materials within the production facility.

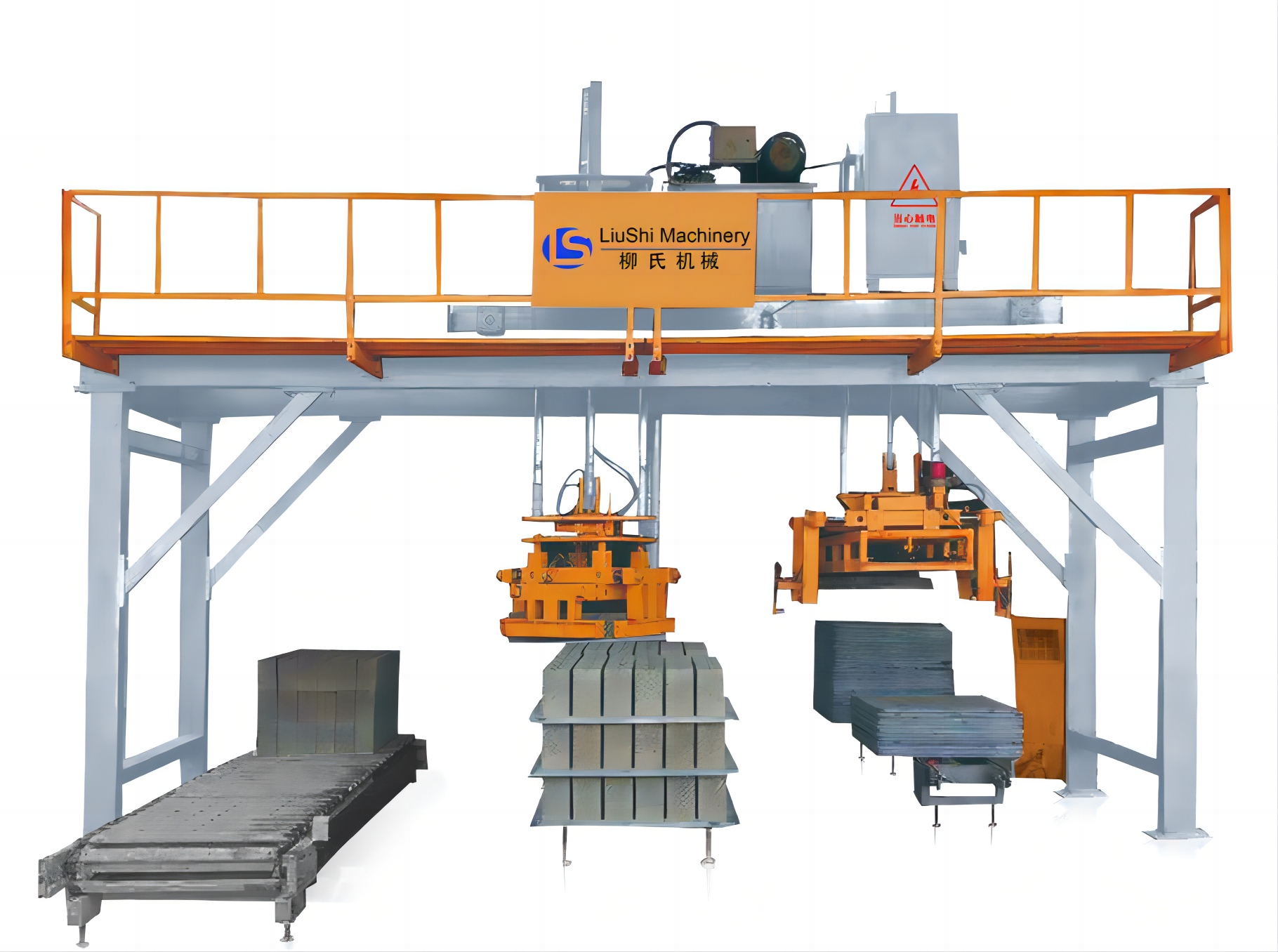

- Overturn Travelling Crane: Used for lifting and moving heavy components.

- Longitudinal Cutting Machine: Cuts large blocks into manageable sizes.

- Transverse Cutting Machine: Provides precise cutting of blocks for consistent shapes.

- Overturn Bottom Travelling Crane: Handles the blocks for further processing.

- Small Steam Car: Transports blocks to the autoclave.

- Still Kettle: The autoclave where the blocks are cured under high pressure and temperature.

- Kettle Travelling Crane: Moves blocks in and out of the autoclave.

- Finished Brick Travelling Crane: Handles finished bricks for storage or transport.

- Side Panel Return Conveyor: Returns side panels for reuse in the production process.

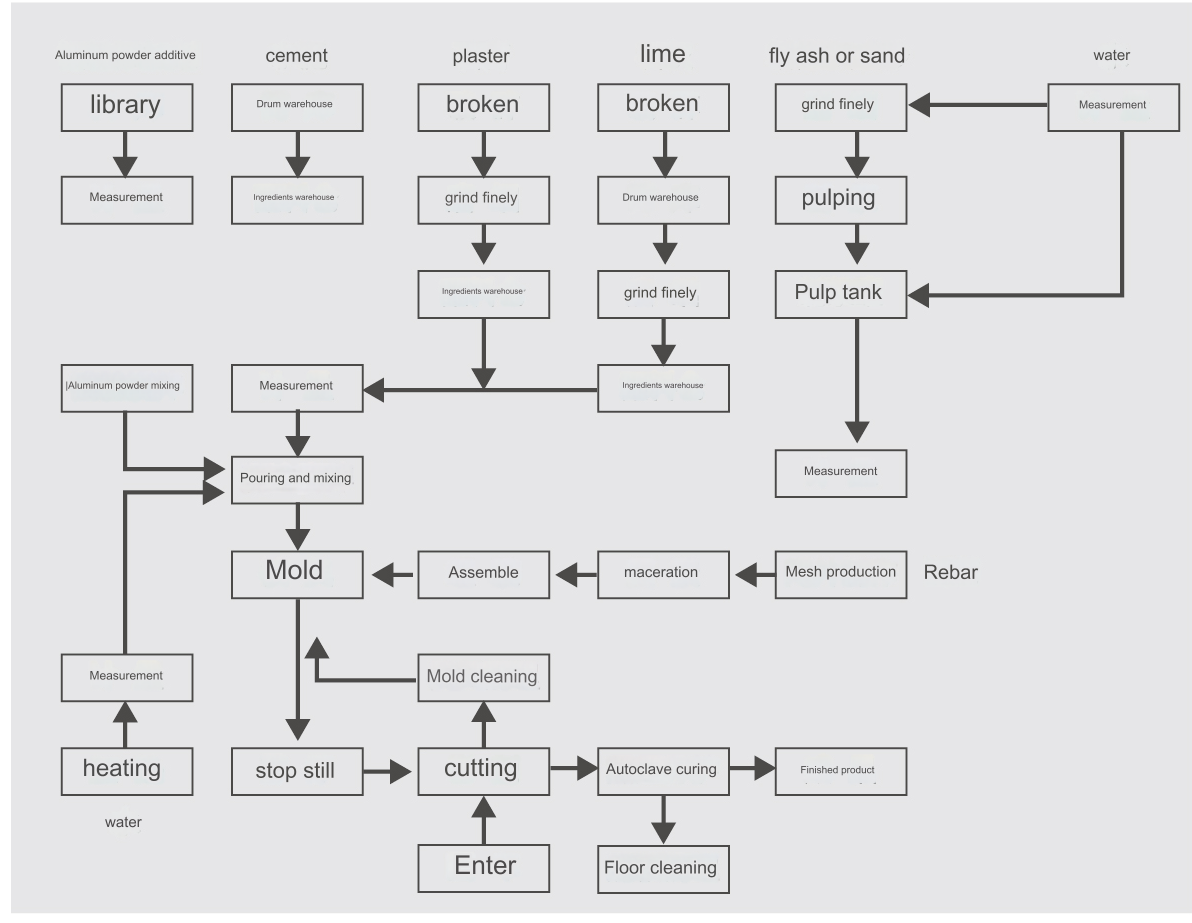

AAC Brick Making Process

Our company can design and produce AAC block production lines with an annual output of 200,000 to 600,000 cubic meters, using fly ash or sand as the main raw material. Here is a brief introduction to the production process:

- Raw Material Preparation: Fly ash or sand is transported and stored. It is then crushed, ground, and screened to ensure uniform particle size.

- Batching and Mixing: Raw materials are accurately measured and mixed to create a slurry, which is then transferred to the storage tank.

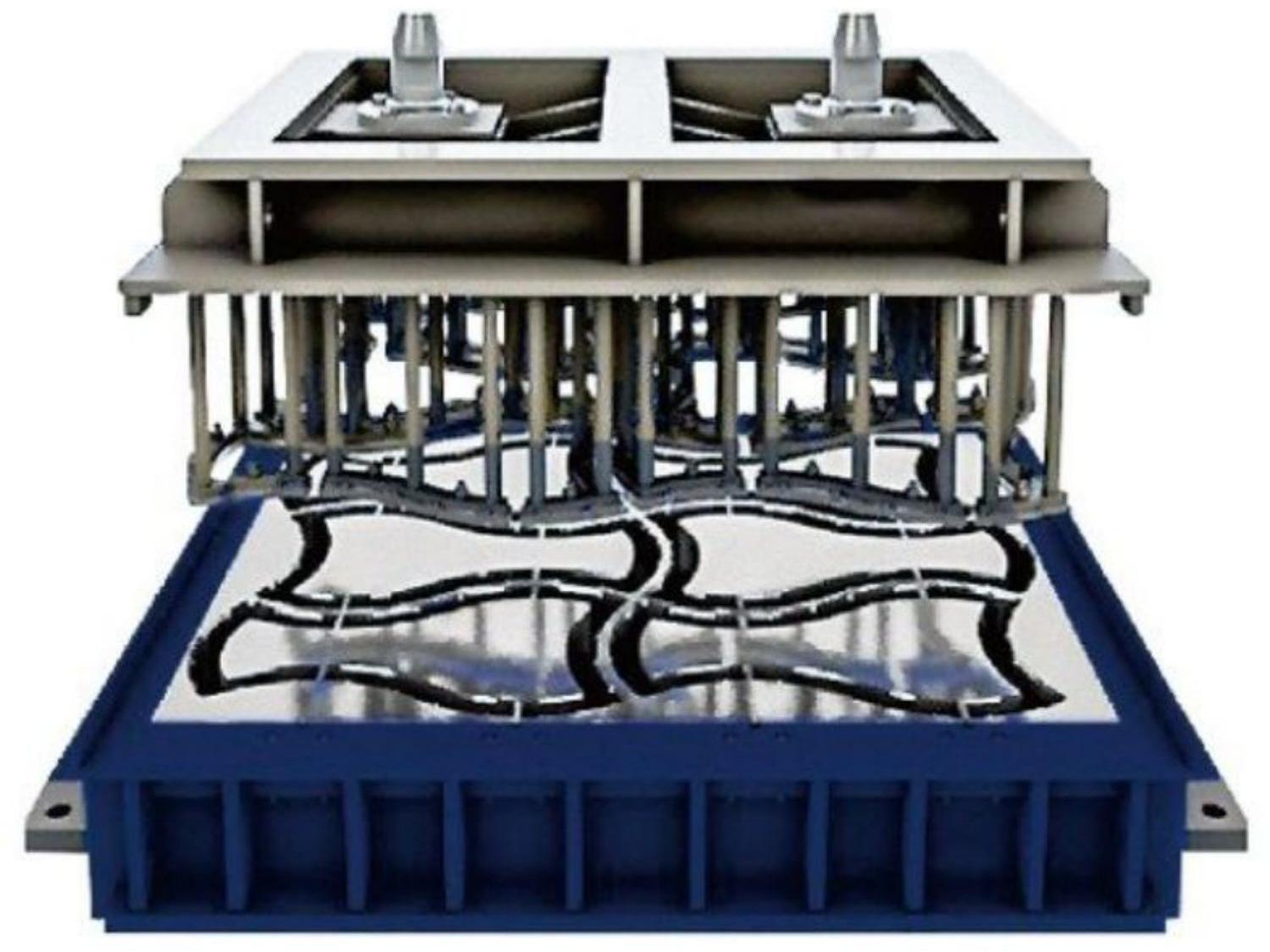

- Molding and Pre-Curing: The slurry is poured into molds and left to pre-cure, forming a solid block that can be easily handled.

- Cutting: Pre-cured blocks are cut into the desired shapes and sizes using longitudinal and transverse cutting machines.

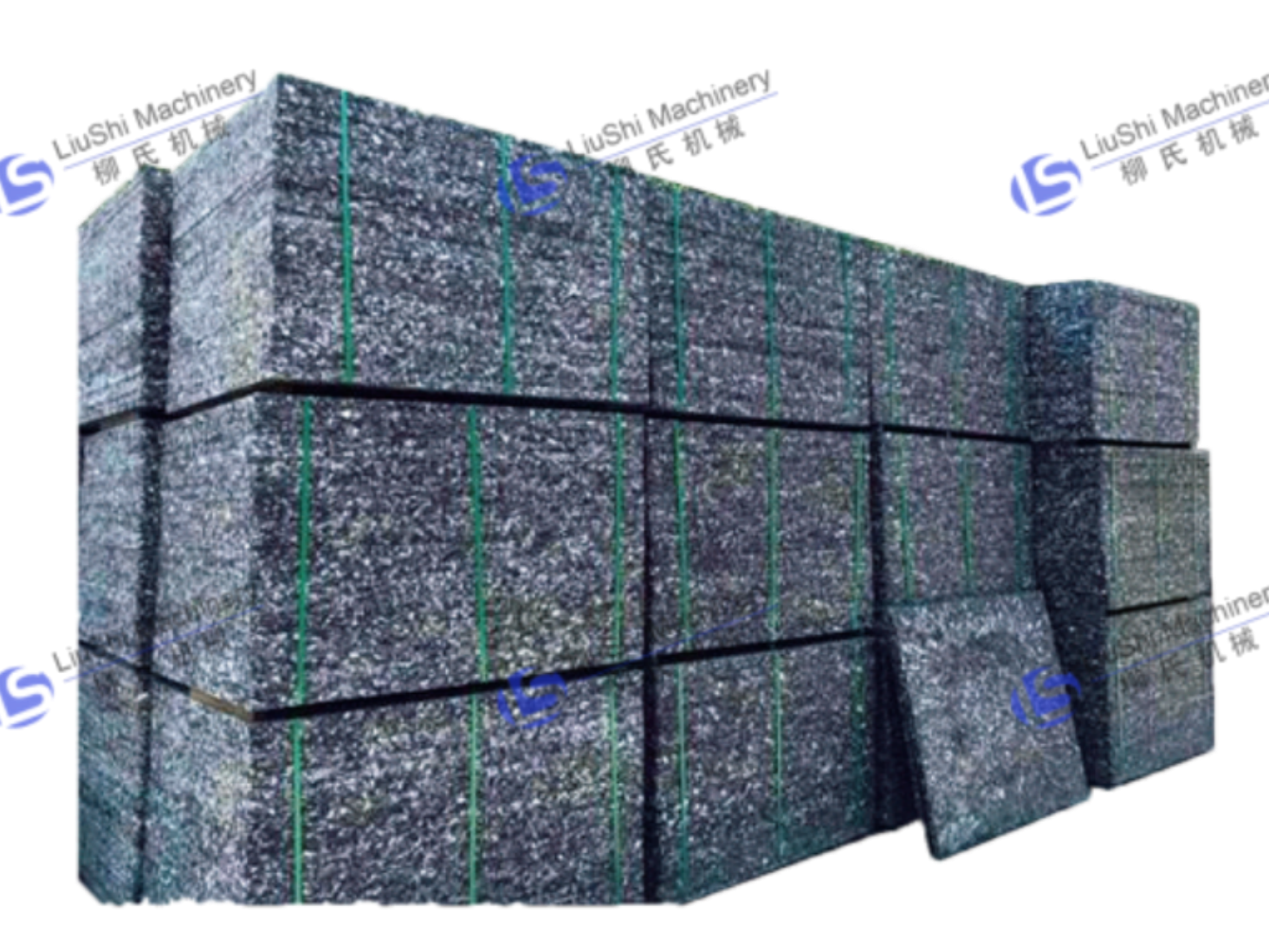

- Autoclaving: Cut blocks are transported to the autoclave, where they are cured under high pressure and temperature to achieve the desired strength and durability.

- Finished Product Handling: Finished AAC blocks are removed from the autoclave, handled by cranes, and transported for storage or delivery.

Company Information

Quanzhou Liushi Machinery Co., Ltd., established in 2006, is a modern technology enterprise integrating R&D, manufacturing, sales, and service. With a strong R&D team and a comprehensive production system, we are committed to enhancing product quality and automation through independent research and development of patented technologies. Our factory covers an area of over 10,000 square meters, and our products are sold to over 1,000 customers domestically and internationally. We have received numerous patents and employ over 100 staff members. We always adhere to the philosophy of "Technology Strengthens the Enterprise" and "Customer First," striving to provide high-quality products and excellent services to our customers.

Contact Us

For more information about our AAC brick production line, please feel free to contact our sales team. We look forward to providing you with high-quality products and satisfactory service.

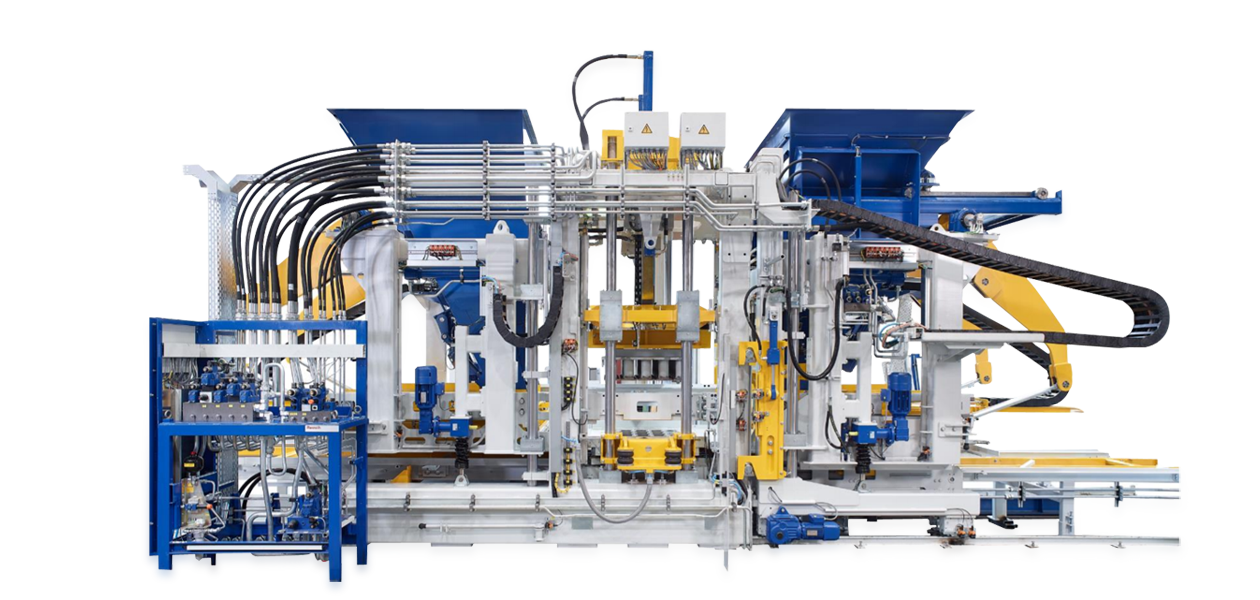

Fully Automatic Block Making Machine

Fully Automatic Block Making Machine Fully Automatic Brick Making Machine Production Line

Fully Automatic Brick Making Machine Production Line AAC Brick Making Machine Production Line

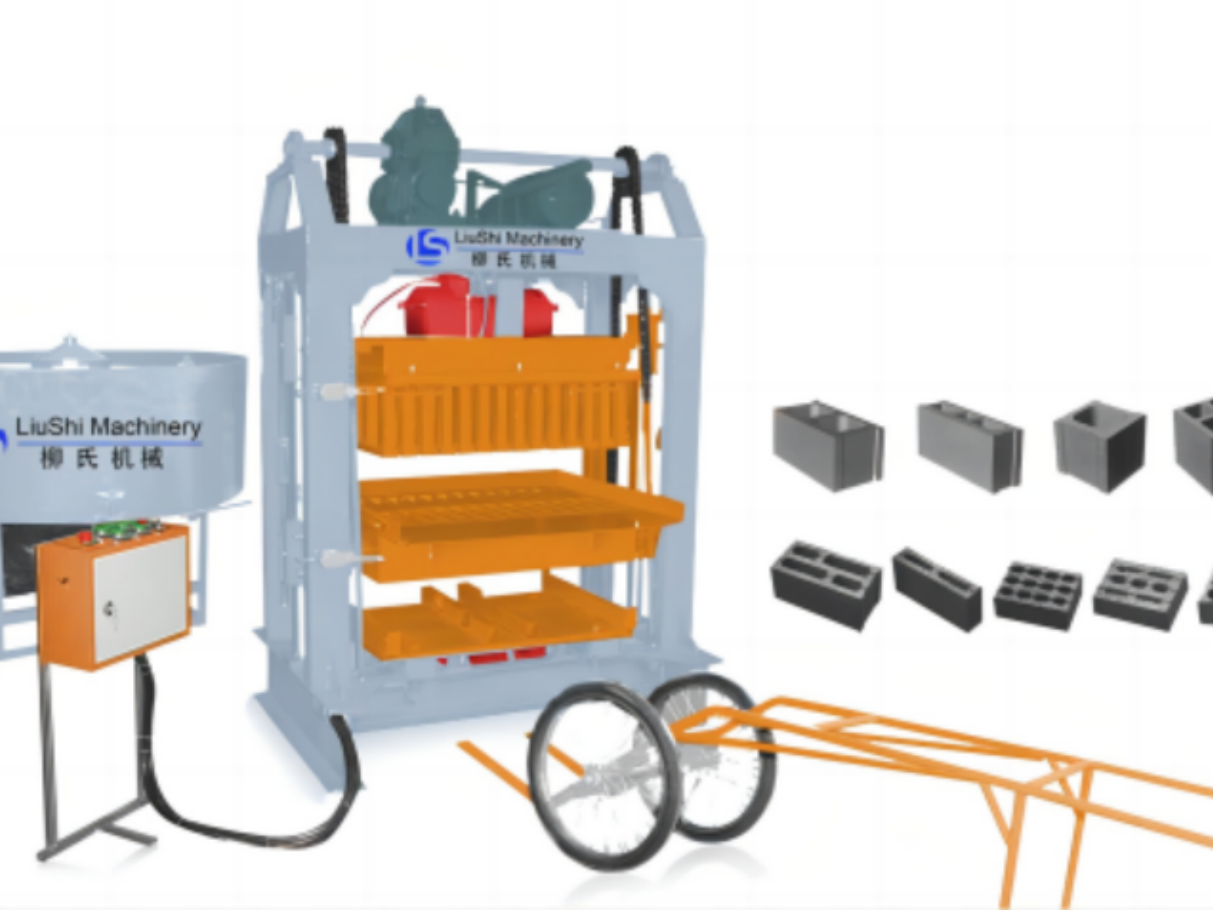

AAC Brick Making Machine Production Line Small Brick Making Machine

Small Brick Making Machine Palletizing System

Palletizing System Concrete Mixer

Concrete Mixer Block Mould

Block Mould Brick Machine Supporting Equipment

Brick Machine Supporting Equipment