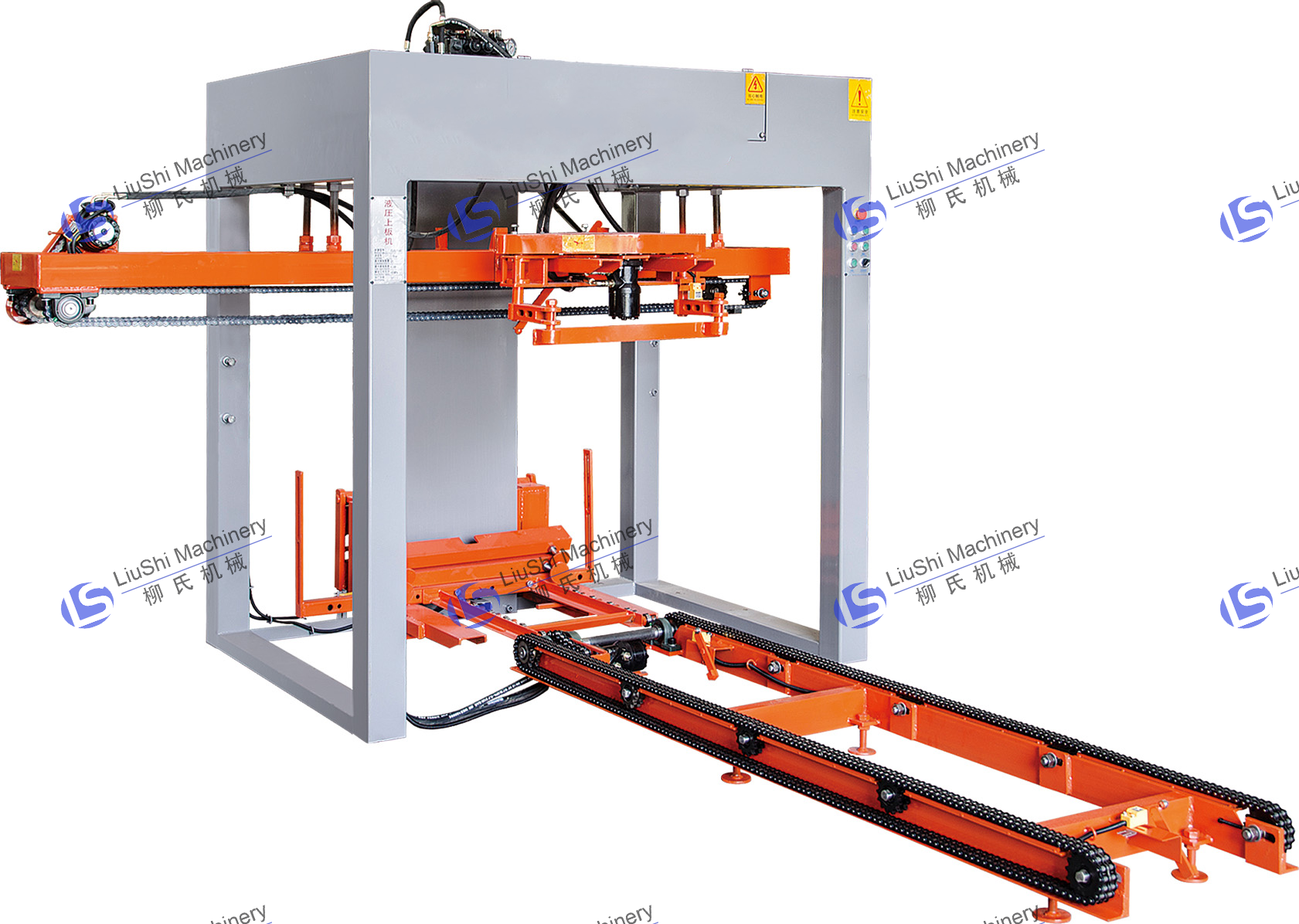

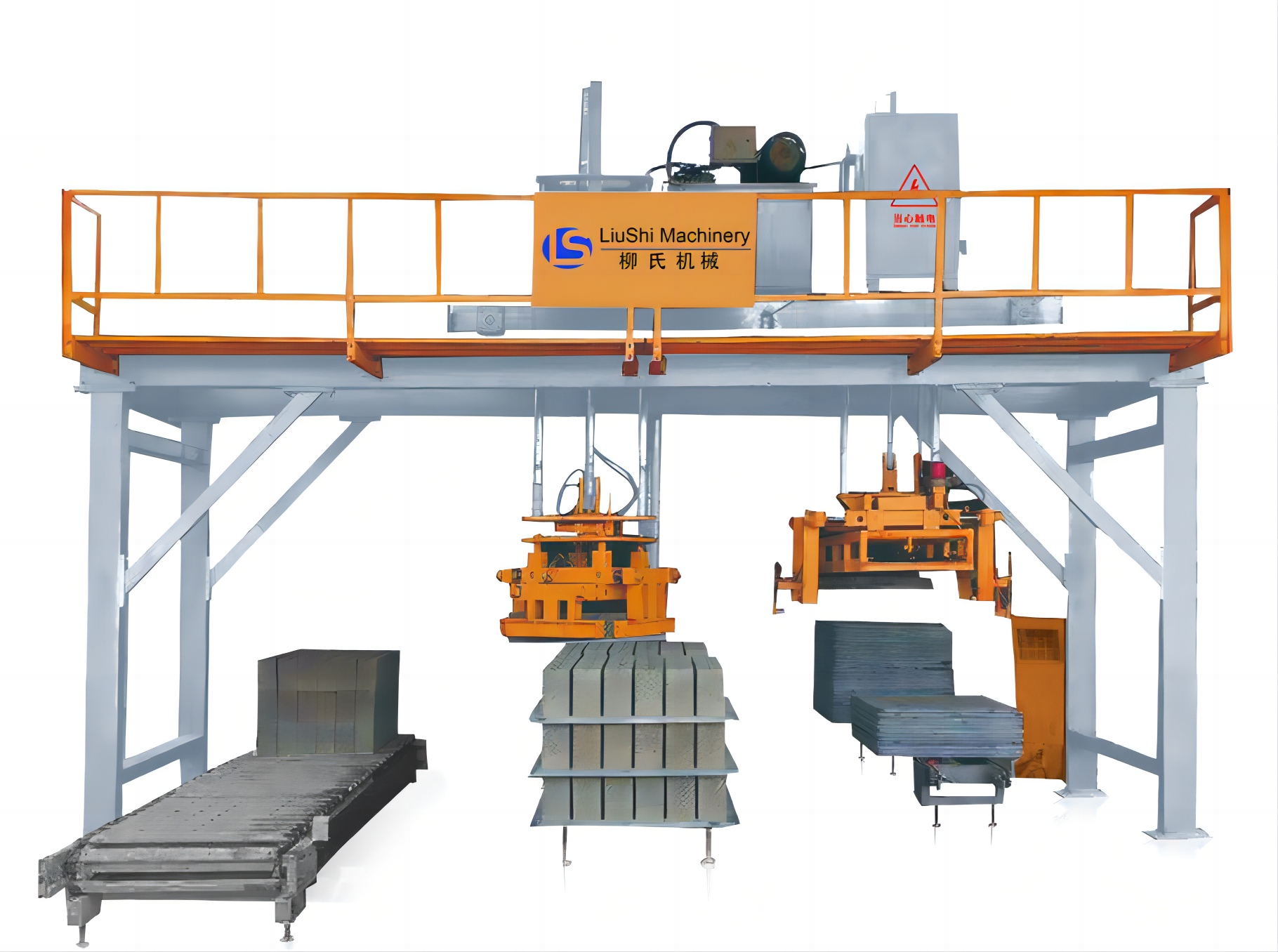

Brick Clamp Machine

Quanzhou Liushi Machinery Co., Ltd. is proud to introduce the Brick Clamp, an essential supporting equipment for brick-making operations. Established in 2006, our company has been at the forefront of the brick machinery industry, specializing in the research, development, manufacturing, sales, and service of high-quality brick-making machinery. The Brick Clamp is a testament to our commitment to innovation and excellence, designed to enhance the efficiency and safety of brick handling processes.

1. Robust Construction The Brick Clamp is engineered with high-strength materials, ensuring exceptional durability and stability during operation. Its robust construction can withstand heavy loads and continuous use, making it an ideal choice for demanding industrial environments.

2. High Precision and Efficiency Equipped with advanced hydraulic systems, the Brick Clamp offers precise and efficient handling of bricks. Its optimized design allows for smooth and accurate clamping, reducing the risk of damage to the bricks and enhancing overall productivity.

3. Versatile Applications The Brick Clamp is designed to handle a wide range of brick sizes and types, including standard bricks, pavers, and blocks. Its adjustable clamping mechanism ensures a secure grip on different brick dimensions, providing versatility and flexibility in various brick-making processes.

4. Easy Integration With its compact and modular design, the Brick Clamp can be easily integrated into existing brick production lines. Its user-friendly interface and straightforward installation process minimize downtime and ensure seamless integration with other equipment.

5. Enhanced Safety Features Safety is a top priority in the design of the Brick Clamp. It is equipped with multiple safety mechanisms, including automatic locking systems and overload protection, to ensure the safety of operators and prevent accidents during operation.

6. Low Maintenance The Brick Clamp is designed for low maintenance and long service life. Its high-quality components and efficient hydraulic system reduce the need for frequent maintenance, lowering operating costs and ensuring reliable performance over time.

Main Technical Parameters

- Clamping Force: Adjustable

- Hydraulic System: Advanced, high-efficiency

- Material: High-strength, durable materials

- Compatibility: Various brick sizes and types

- Safety Features: Automatic locking, overload protection

About Our Company

Quanzhou Liushi Machinery Co., Ltd. was established in 2006 and is a modern technological enterprise specializing in the research, development, manufacturing, sales, and service of brick-making machinery. We have a strong R&D team, awarded as a high-tech enterprise with self-developed patented technology. Embracing the "Internet+" concept in the context of Industry 4.0, we continuously enhance the "Technology Strengthens Enterprise" philosophy to reach advanced industry levels.

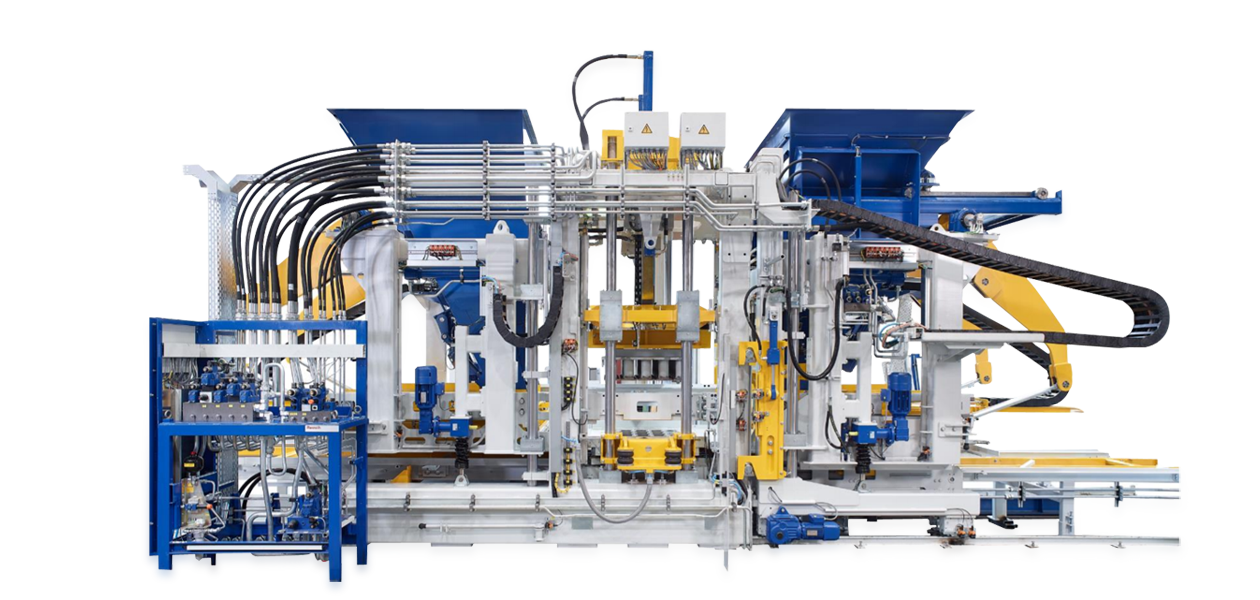

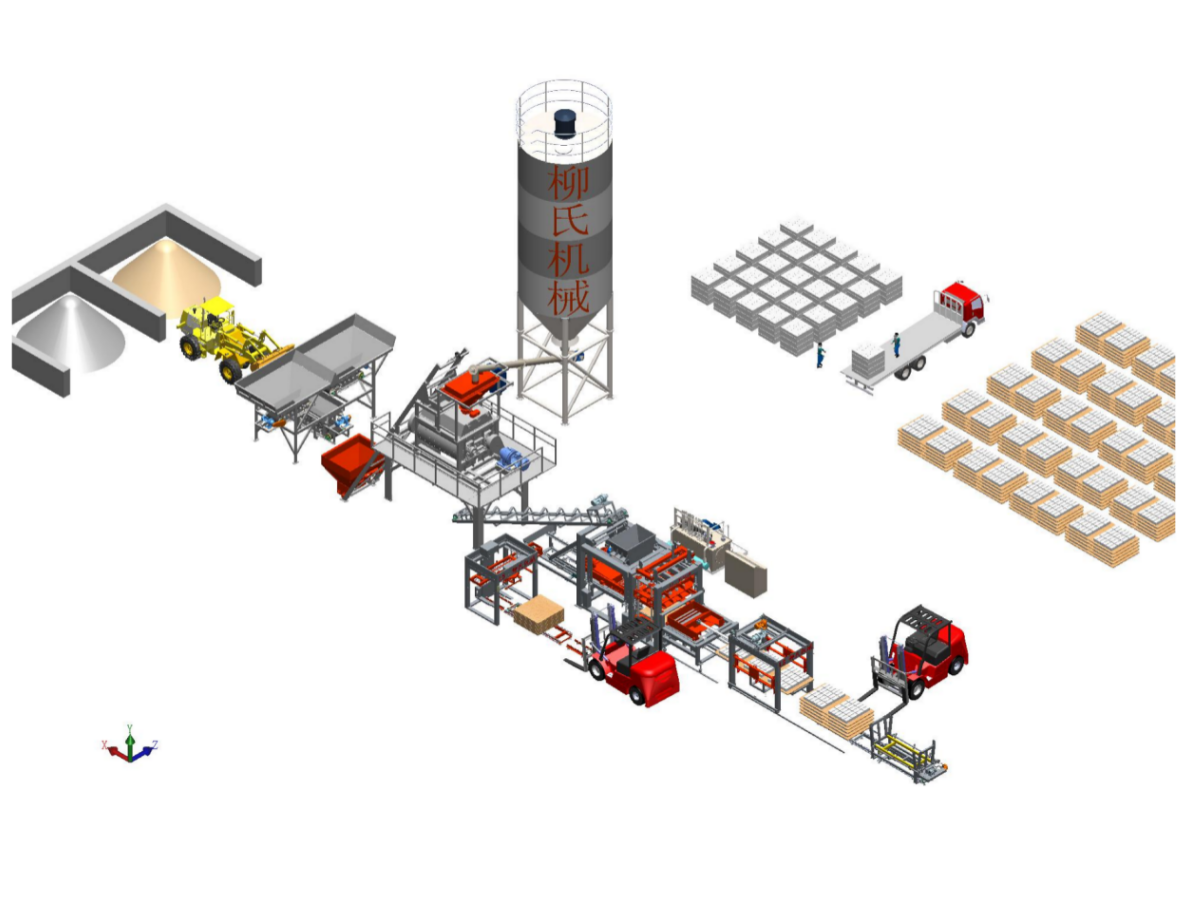

Comprehensive Production System: Our "LS" series non-burning brick machines (cement brick machines) include fully automatic forming brick machines, pallet-free brick machines, hydraulic brick machines, and more, characterized by high automation, stable quality, strong durability, and high production efficiency.

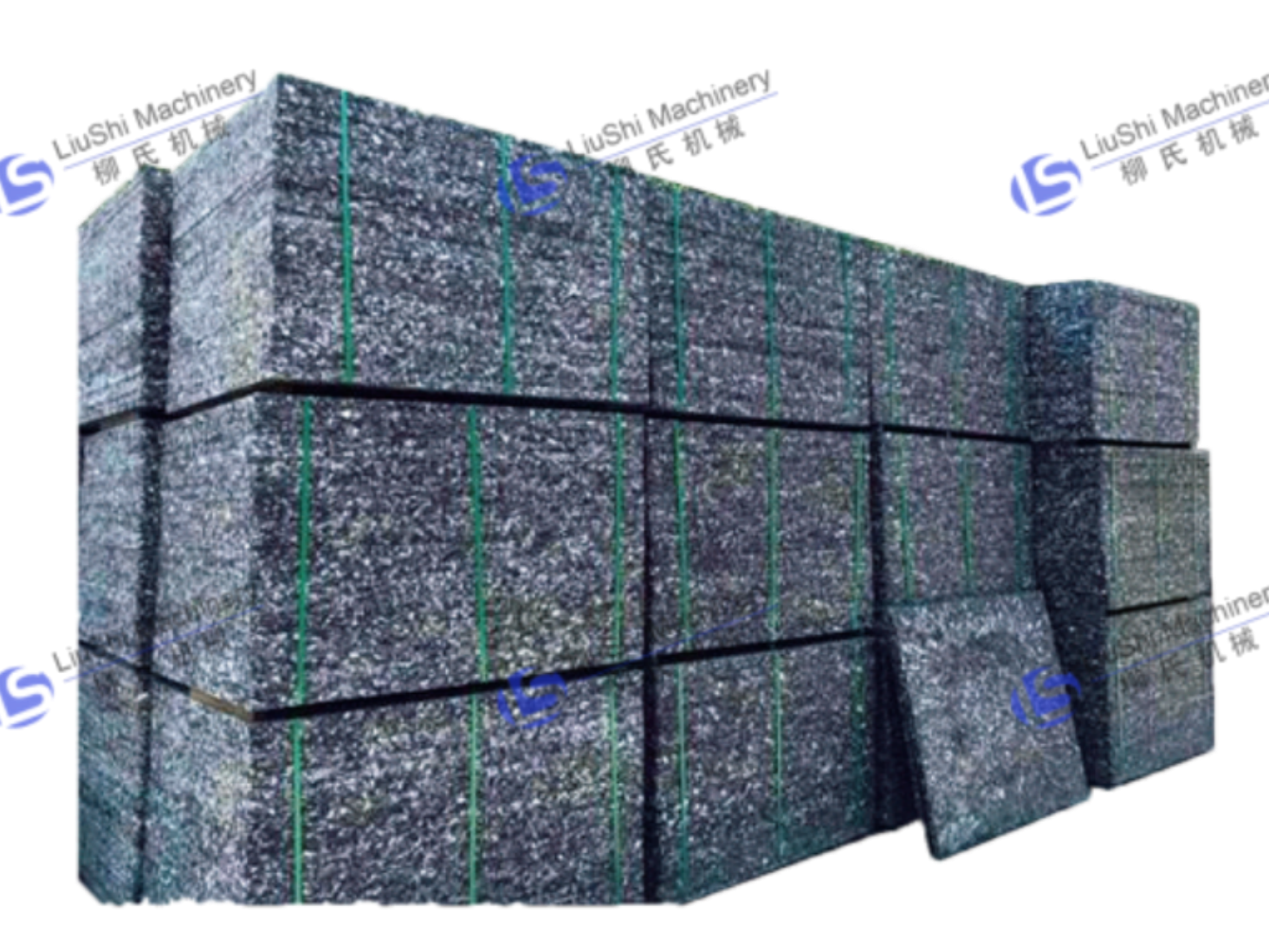

Customized Solutions: We offer customized solutions according to user requirements, specializing in the production of non-burning cement brick machines: static pressure brick machines, pallet-free brick machines, fully automatic block forming machines, brick packing machines, cement brick curing kilns, and more. These machines are suitable for producing various specifications of colored pavement bricks, interlocking blocks, grass bricks, ecological slope protection bricks, imitation stone curbs, imitation stone PC bricks, and clear water wall bricks.

Our factory covers an area of over 10,000 square meters, with products sold domestically and internationally, over 1,000 customers, more than 50 patents, and a workforce of over 100 employees.

Fully Automatic Block Making Machine

Fully Automatic Block Making Machine Fully Automatic Brick Making Machine Production Line

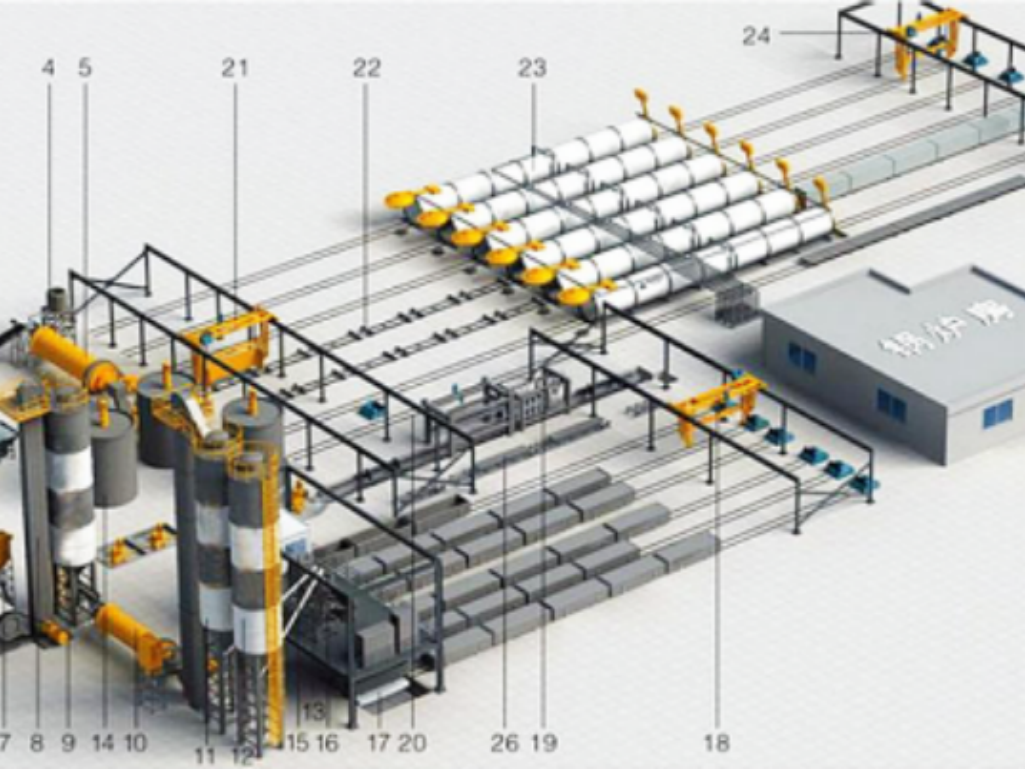

Fully Automatic Brick Making Machine Production Line AAC Brick Making Machine Production Line

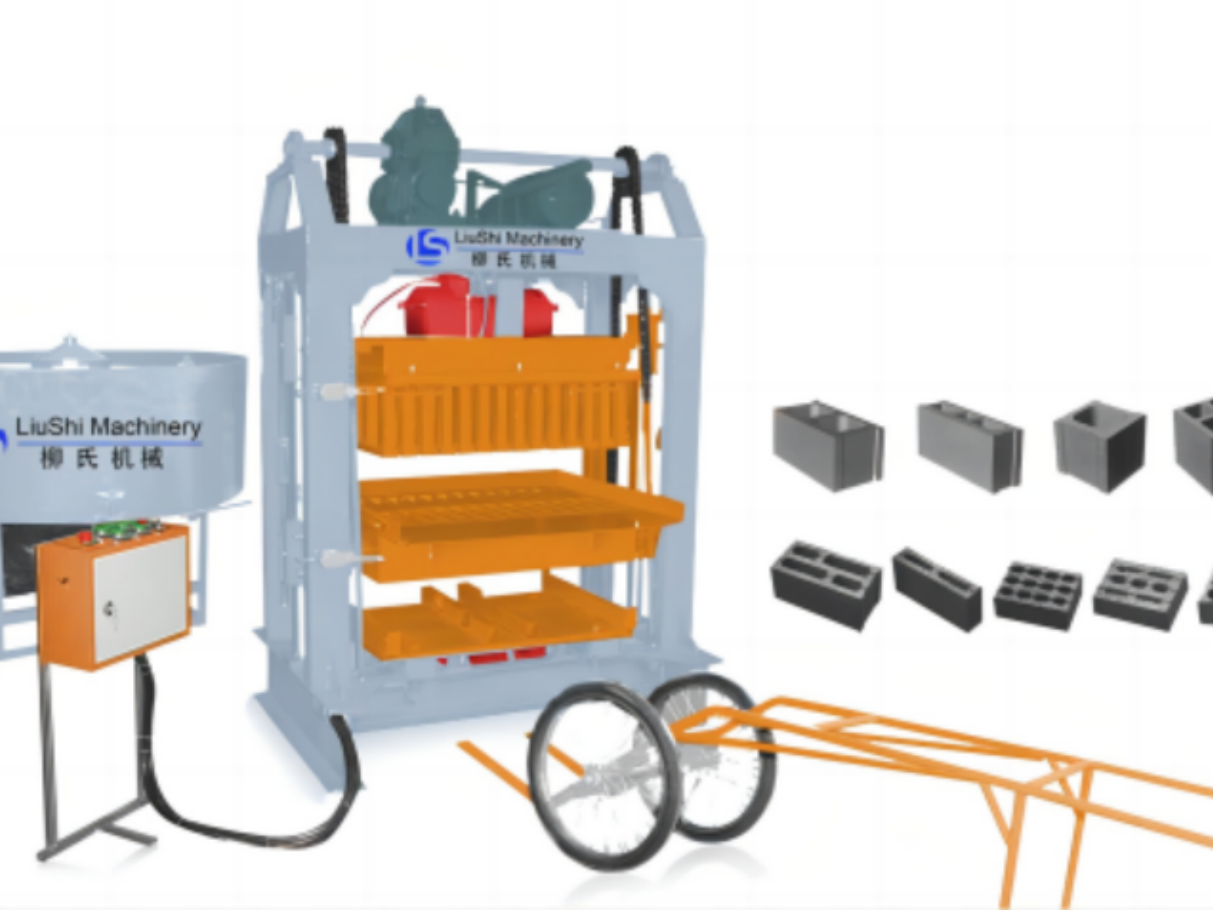

AAC Brick Making Machine Production Line Small Brick Making Machine

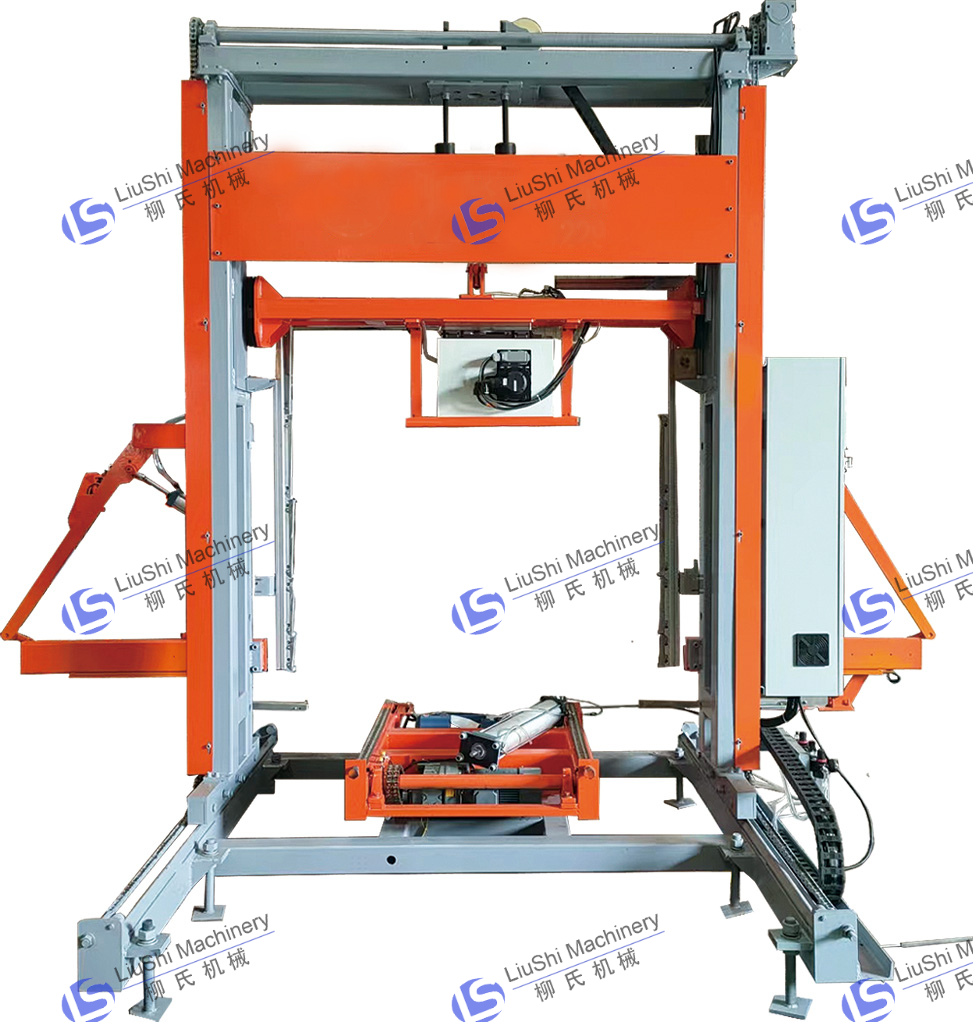

Small Brick Making Machine Palletizing System

Palletizing System Concrete Mixer

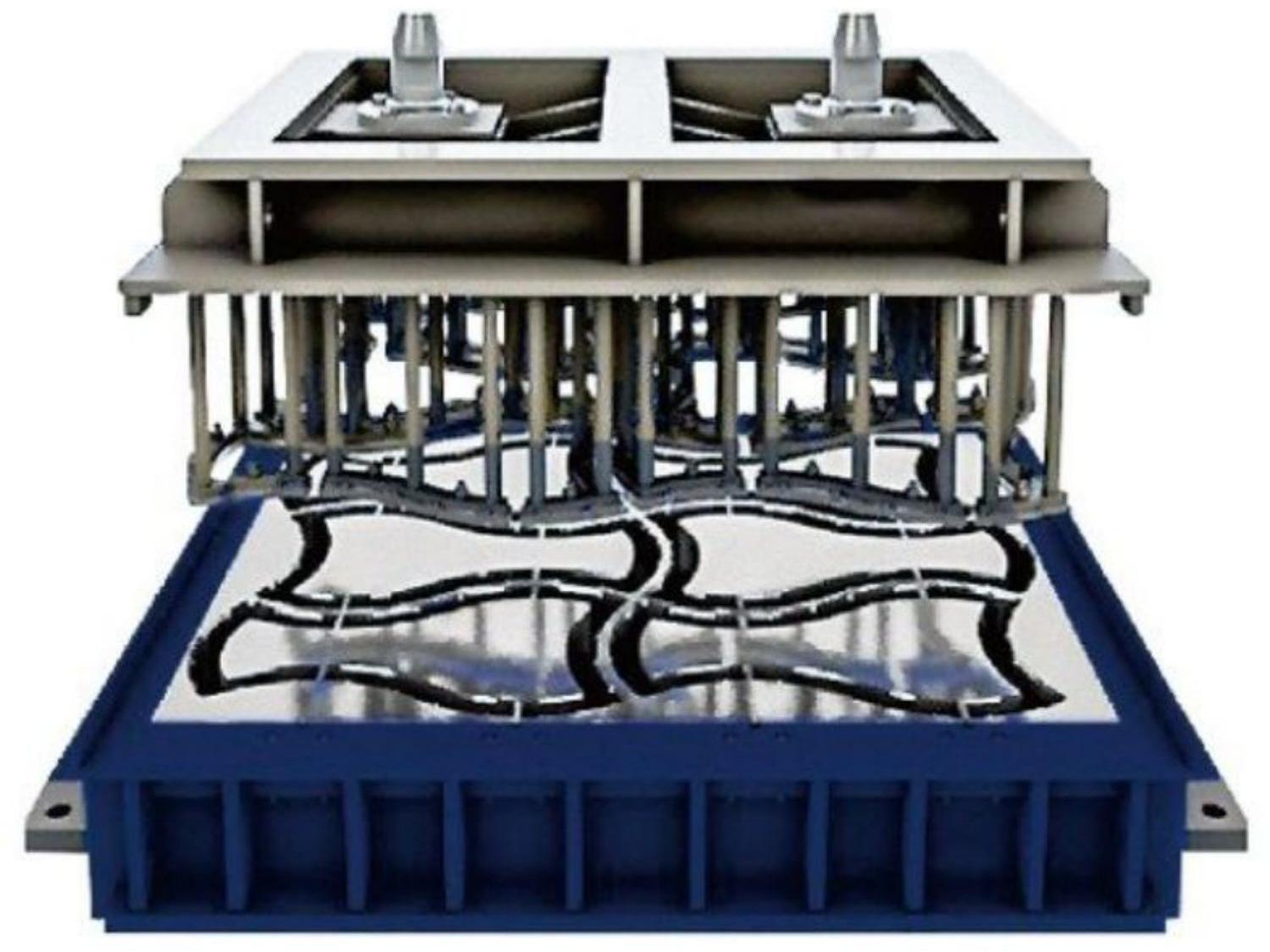

Concrete Mixer Block Mould

Block Mould Brick Machine Supporting Equipment

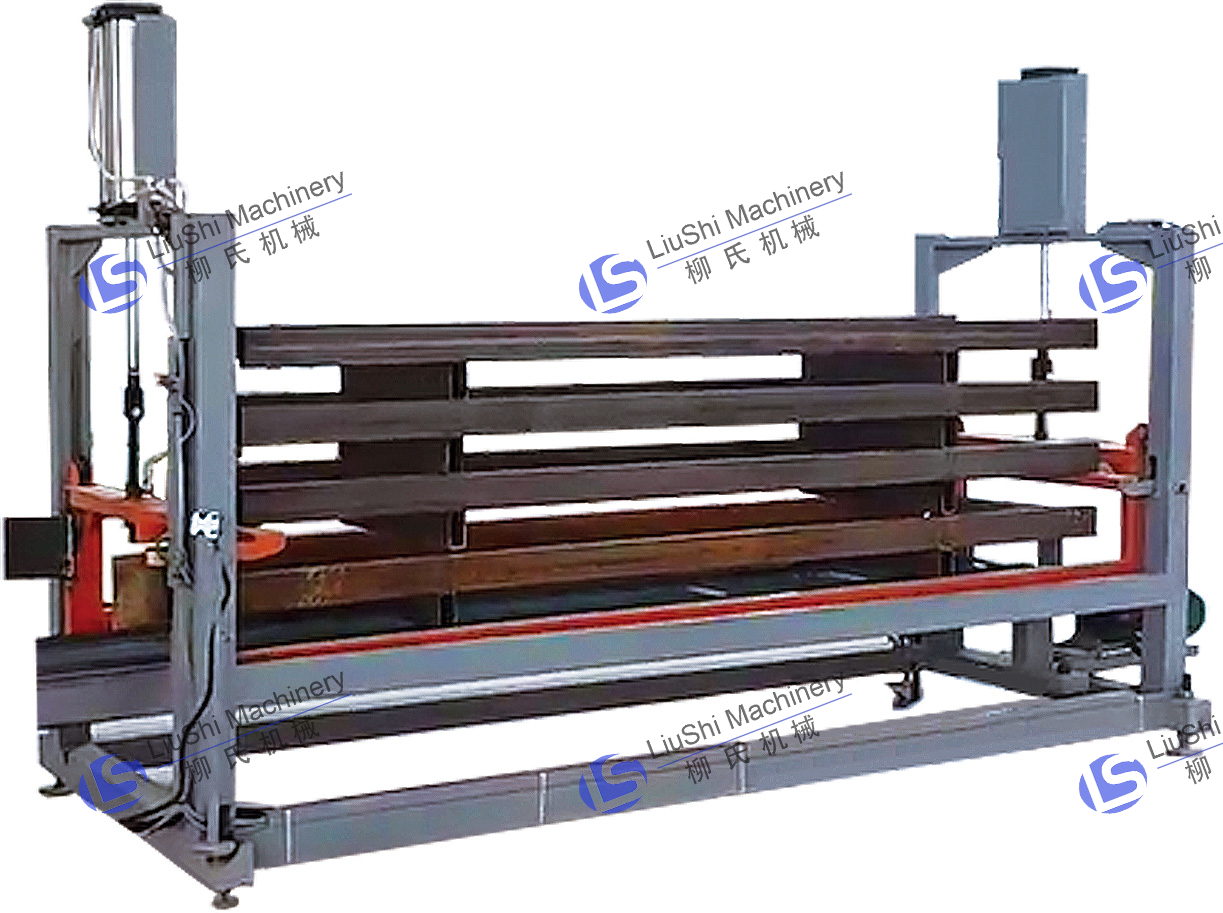

Brick Machine Supporting Equipment