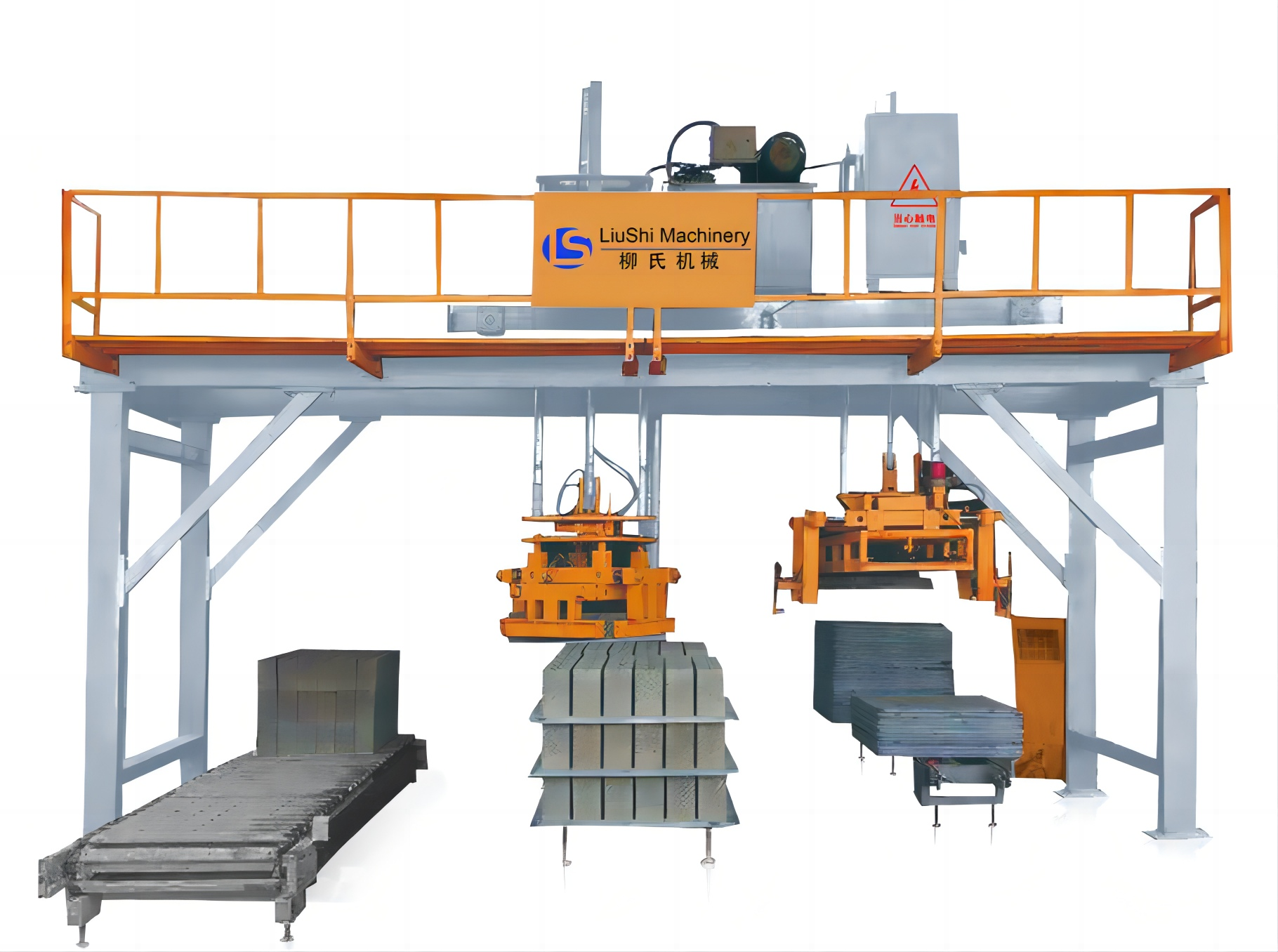

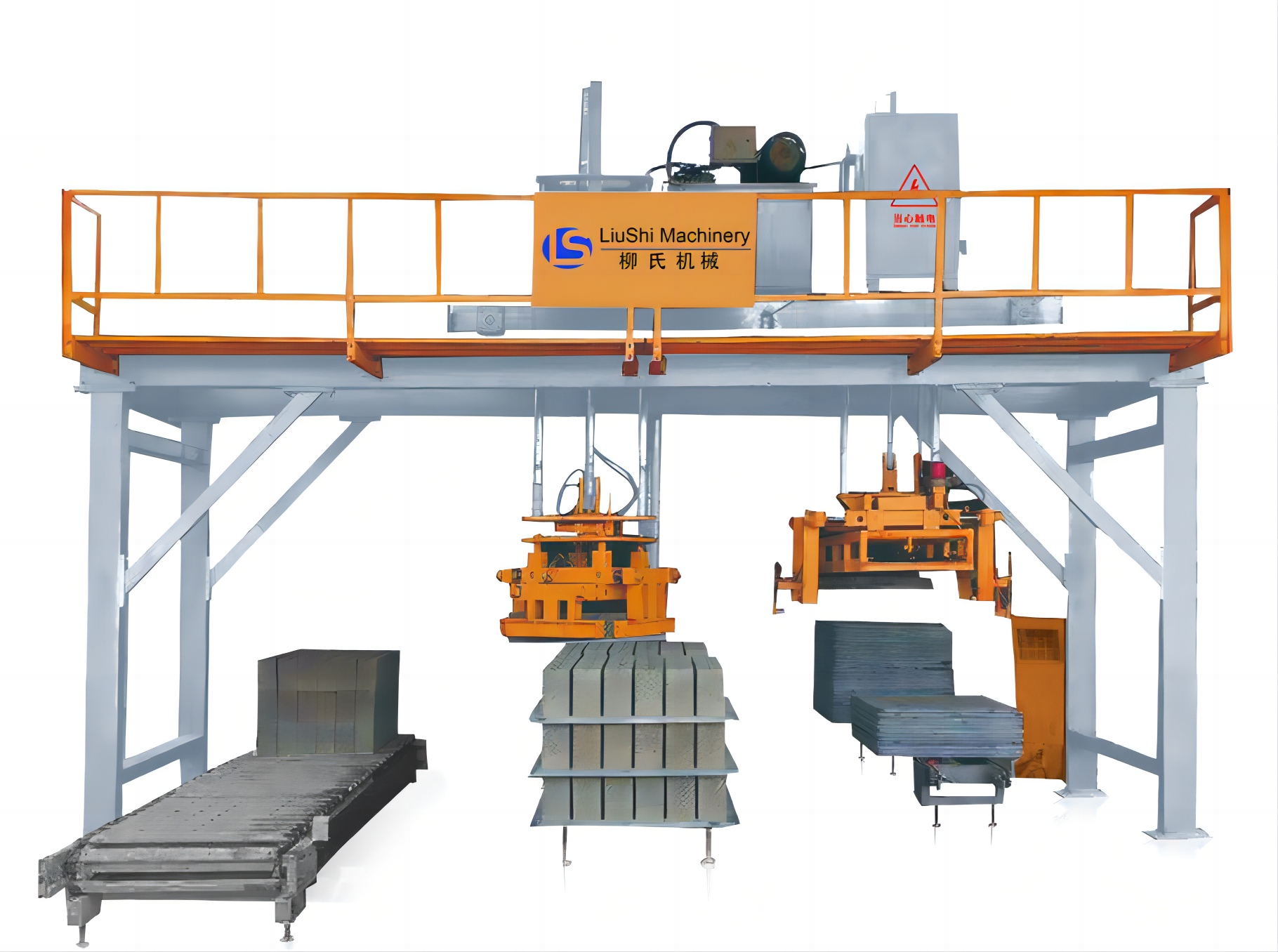

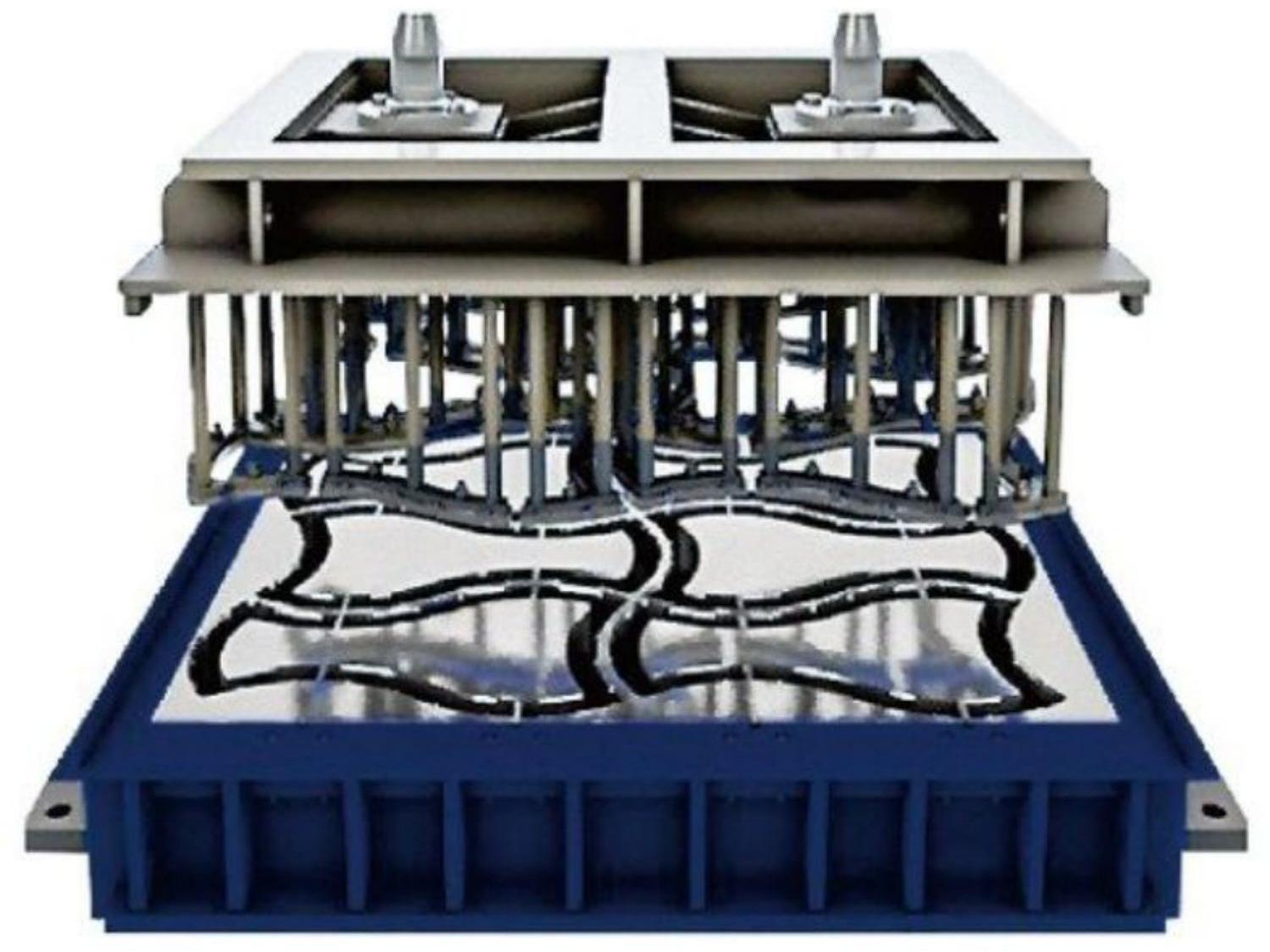

LSH-1200 High-Level Offline Palletizing System

The LSH-1200 high-level offline palletizing system by Quanzhou Liushi Machinery Co., Ltd. is designed for efficient and precise brick palletizing. This advanced system offers an optional servo control for horizontal movement and rotation, ensuring stable operation at both high and low speeds, and achieving closed-loop control of position, speed, and torque. The lifting mechanism is controlled by an encoder and proportional valve, enabling fast rise, fast fall, slow rise, and slow fall functions for precise palletizing height. Users can adjust the rotation angle, palletizing layers, and palletizing height according to their needs.

Key Technical Parameters:

- Whole Line Area: 18500mm (L) x 11800mm (W) (Equipment working height 6800mm)

- Applicable Pallet Specifications: Customized according to user requirements

- Palletizing Specifications: 1000mm x 1000mm x 1200mm, 1200mm x 1200mm x 1200mm

- Adaptive Brick Height: 50mm ~ 200mm

- Palletizing Period: 12~15 seconds per layer

- Palletizing Deviation: ±5mm

- Take-up Height: 800mm

- Whole Line Electrical Power: 60kW

Features

- Servo Control System: Optional servo control for horizontal movement and rotation ensures stable and precise operation at both high and low speeds.

- Closed-Loop Control: Achieves closed-loop control of position, speed, and torque for precise palletizing.

- Lifting Control: Encoder and proportional valve control enable fast rise, fast fall, slow rise, and slow fall functions, ensuring accurate palletizing height.

- Adjustable Parameters: Users can adjust the rotation angle, palletizing layers, and palletizing height to suit different brick specifications and palletizing needs.

- High Efficiency: Short palletizing cycle, with an average of 12~15 seconds per layer, significantly improving production efficiency.

- High Precision: Palletizing deviation of only ±5mm ensures precise stacking of each brick layer.

Company Information

Quanzhou Liushi Machinery Co., Ltd. was established in 2006 and is a modern technology enterprise specializing in the research, development, manufacturing, sales, and service of brick-making machinery. The company boasts a strong R&D team, holding multiple high-tech enterprise certifications and independent patents. In the era of Industry 4.0, the company leverages "Internet+" to continuously strengthen its "technology-driven enterprise" philosophy, achieving industry-leading standards.

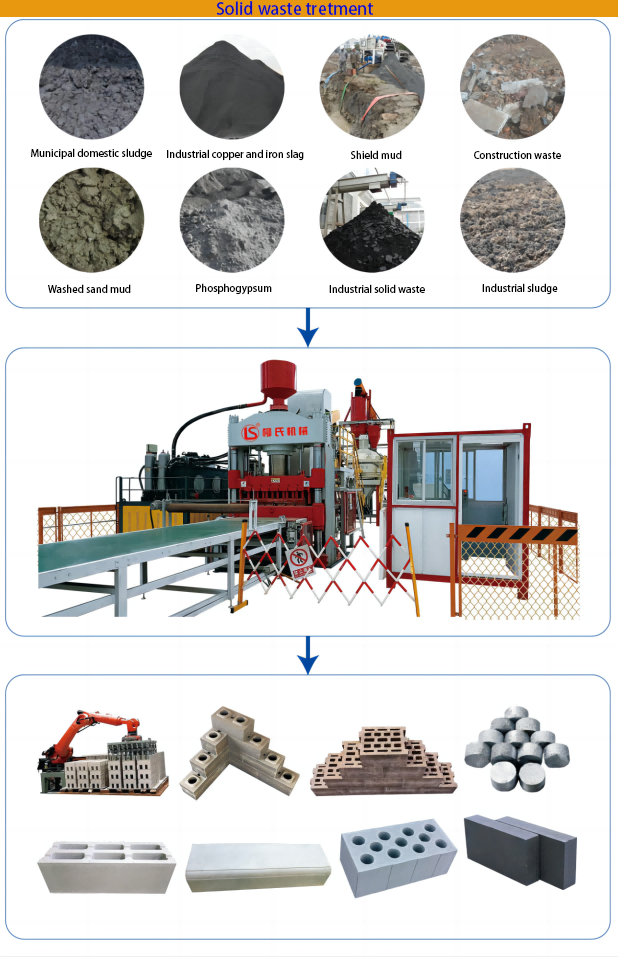

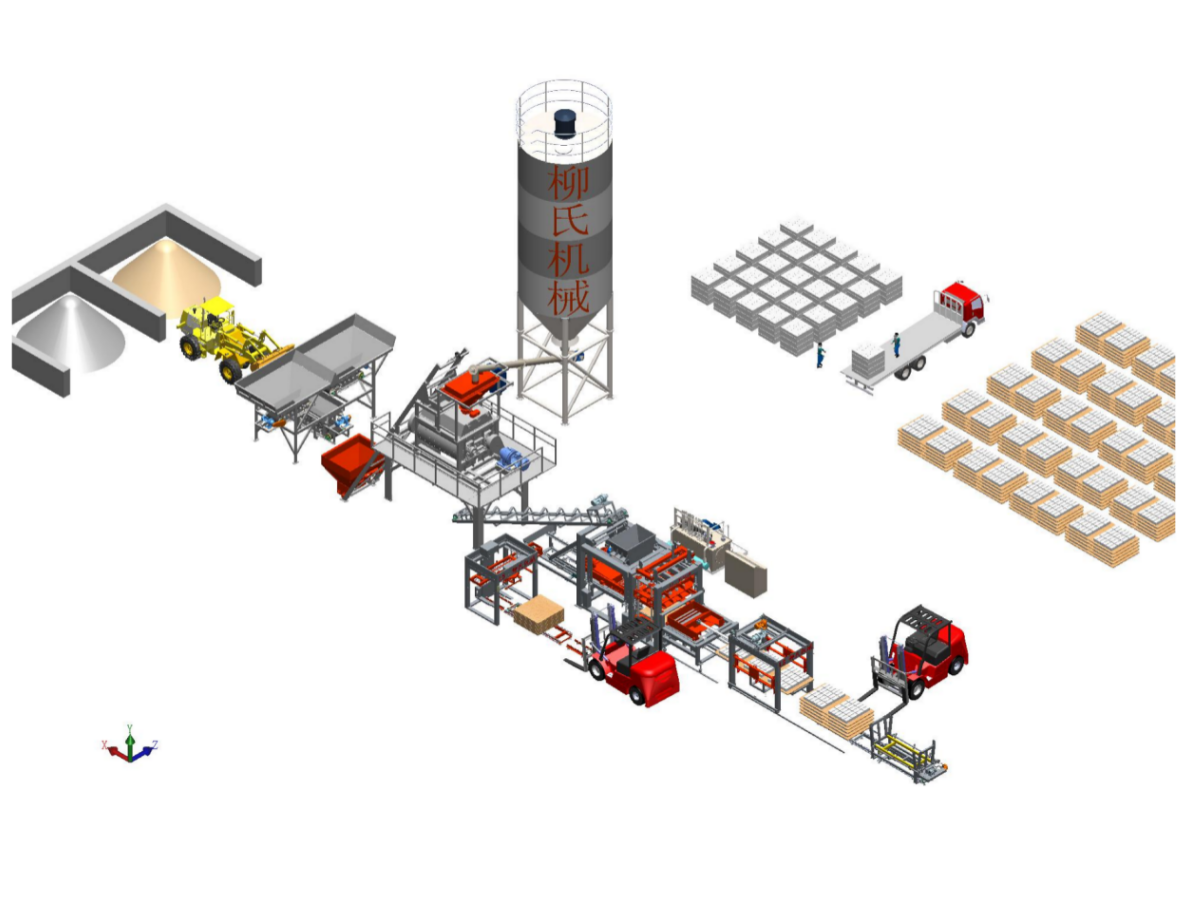

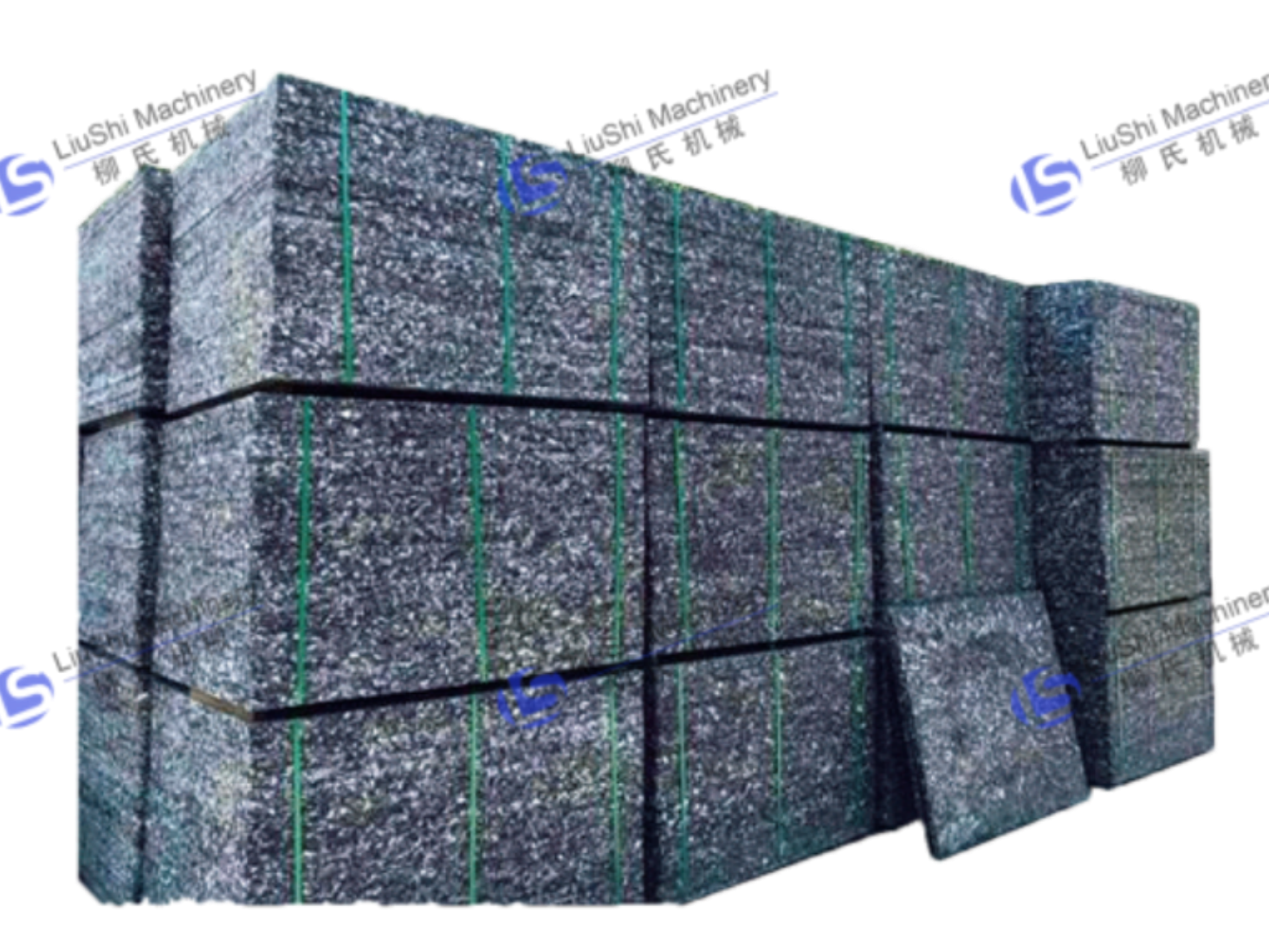

Comprehensive Production System: The company produces the "LS" series of non-fired brick machines (including fully automatic molding brick machines, pallet-free brick machines, hydraulic brick machines, etc.), which are highly automated, stable in quality, durable, and efficient in production.

Customizable Solutions: The company offers customized solutions according to user needs, specializing in the production of non-fired cement brick machines, static pressure brick machines, pallet-free brick machines, fully automatic block forming machines, brick stacking and packaging machines, cement brick curing kiln lines, and other machinery. These machines are suitable for producing various specifications of colored pavement bricks, interlocking blocks, grass bricks, ecological slope protection bricks, imitation stone curbstones, imitation stone PC bricks, fair-faced wall bricks, and other construction bricks.

Company Strength:

- Factory Area: 10,000+ square meters

- Sales: Over 1,000 customers domestically and internationally

- Patents: 50+ patents

- Employees: 100+ staff

Contact Us

For more information about the LSH-1200 high-level offline palletizing system, please contact our sales team. We look forward to providing you with high-quality products and excellent service.

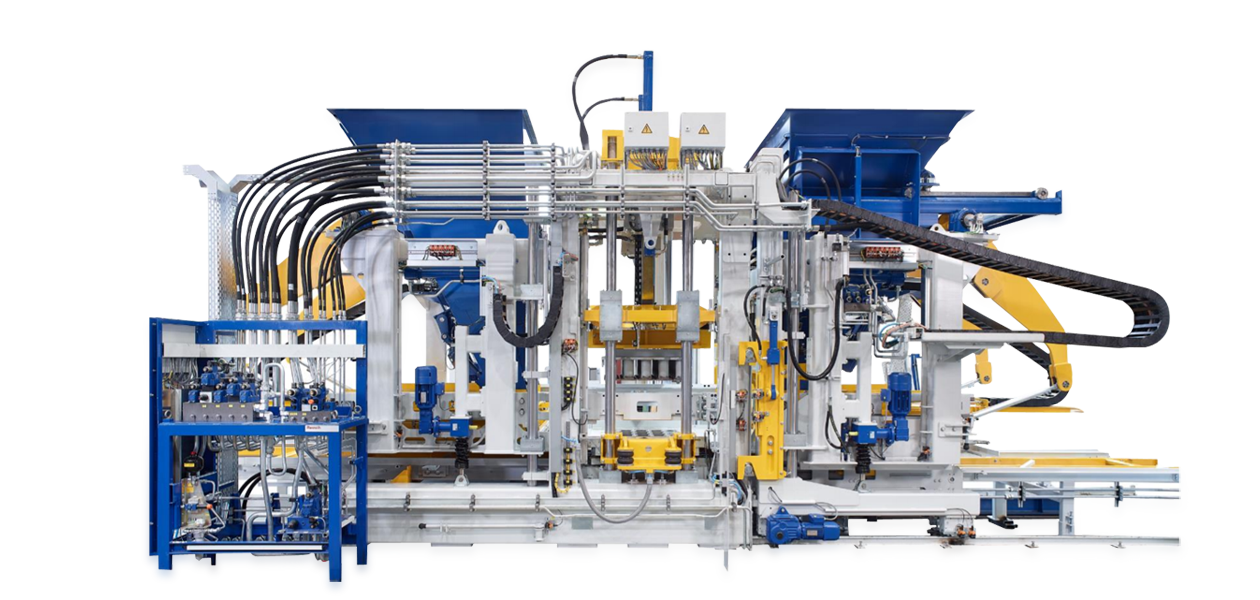

Fully Automatic Block Making Machine

Fully Automatic Block Making Machine Fully Automatic Brick Making Machine Production Line

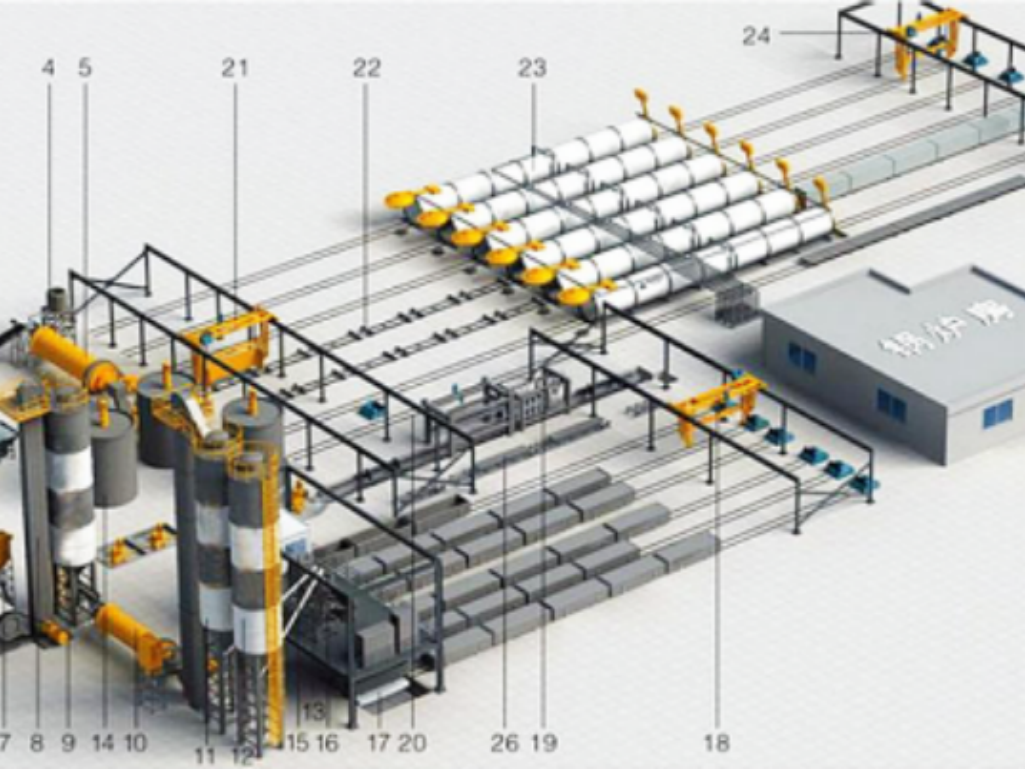

Fully Automatic Brick Making Machine Production Line AAC Brick Making Machine Production Line

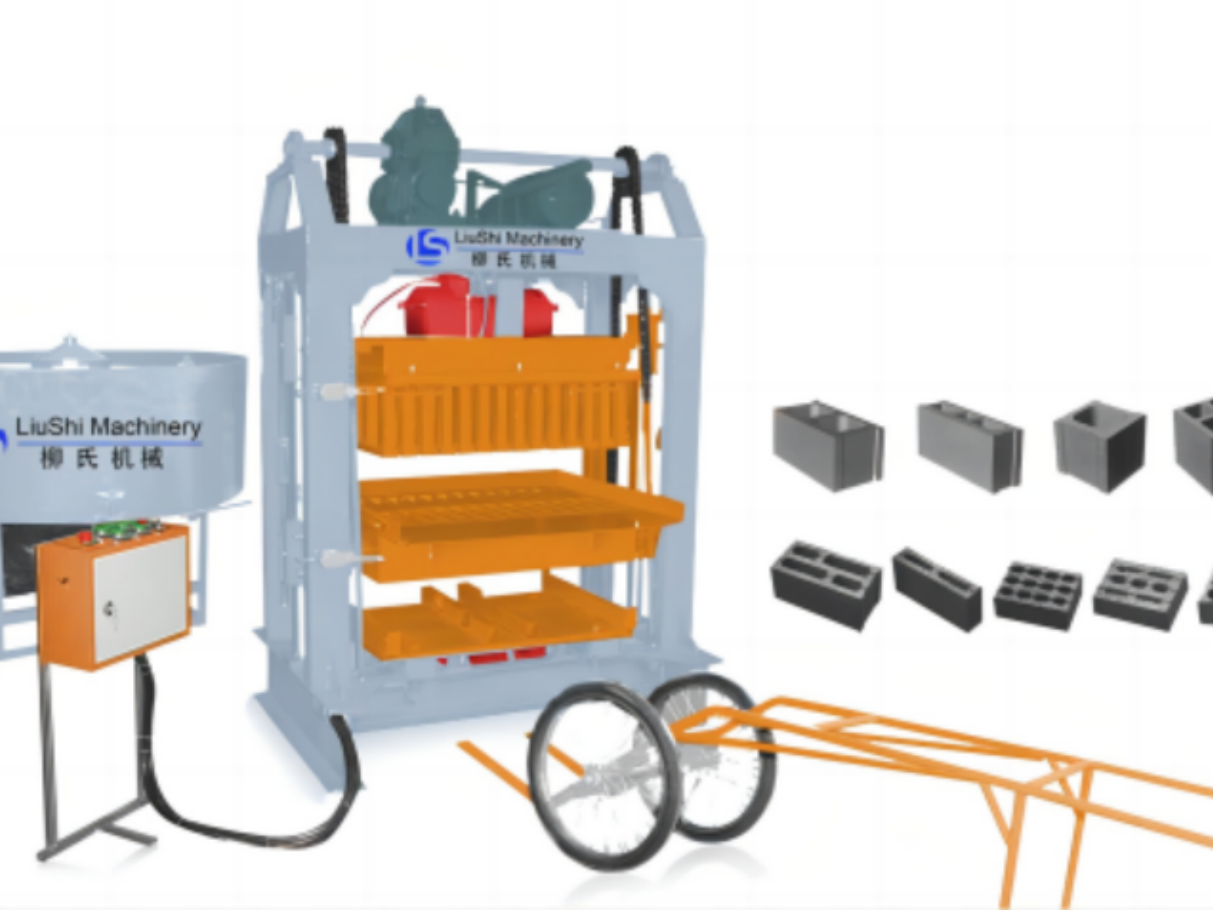

AAC Brick Making Machine Production Line Small Brick Making Machine

Small Brick Making Machine Palletizing System

Palletizing System Concrete Mixer

Concrete Mixer Block Mould

Block Mould Brick Machine Supporting Equipment

Brick Machine Supporting Equipment