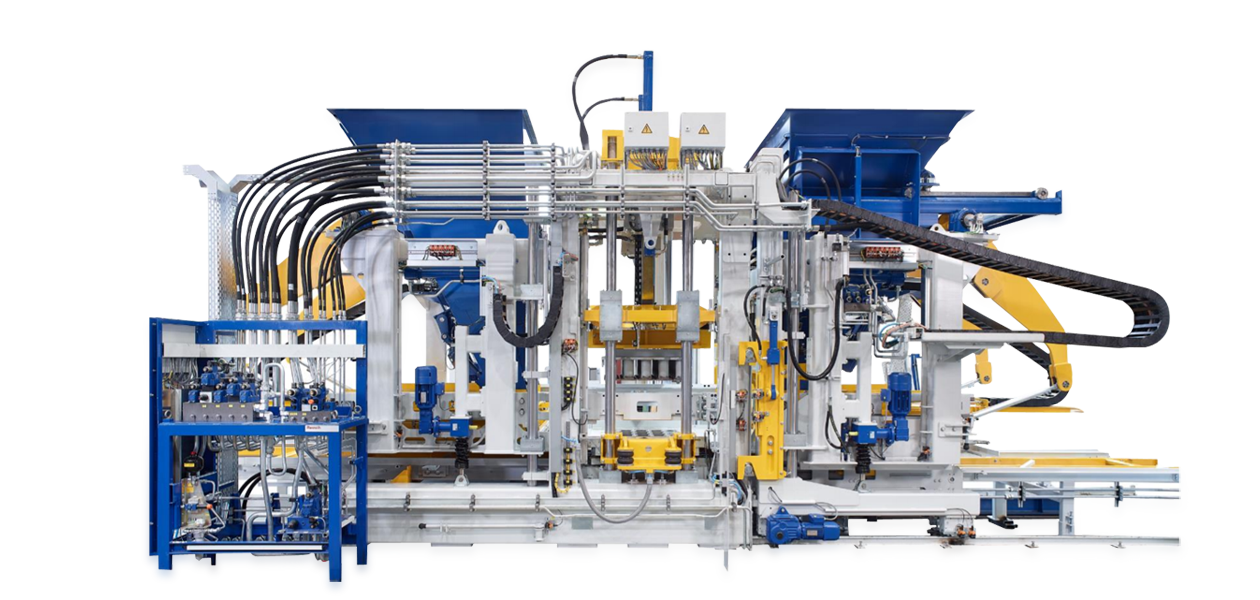

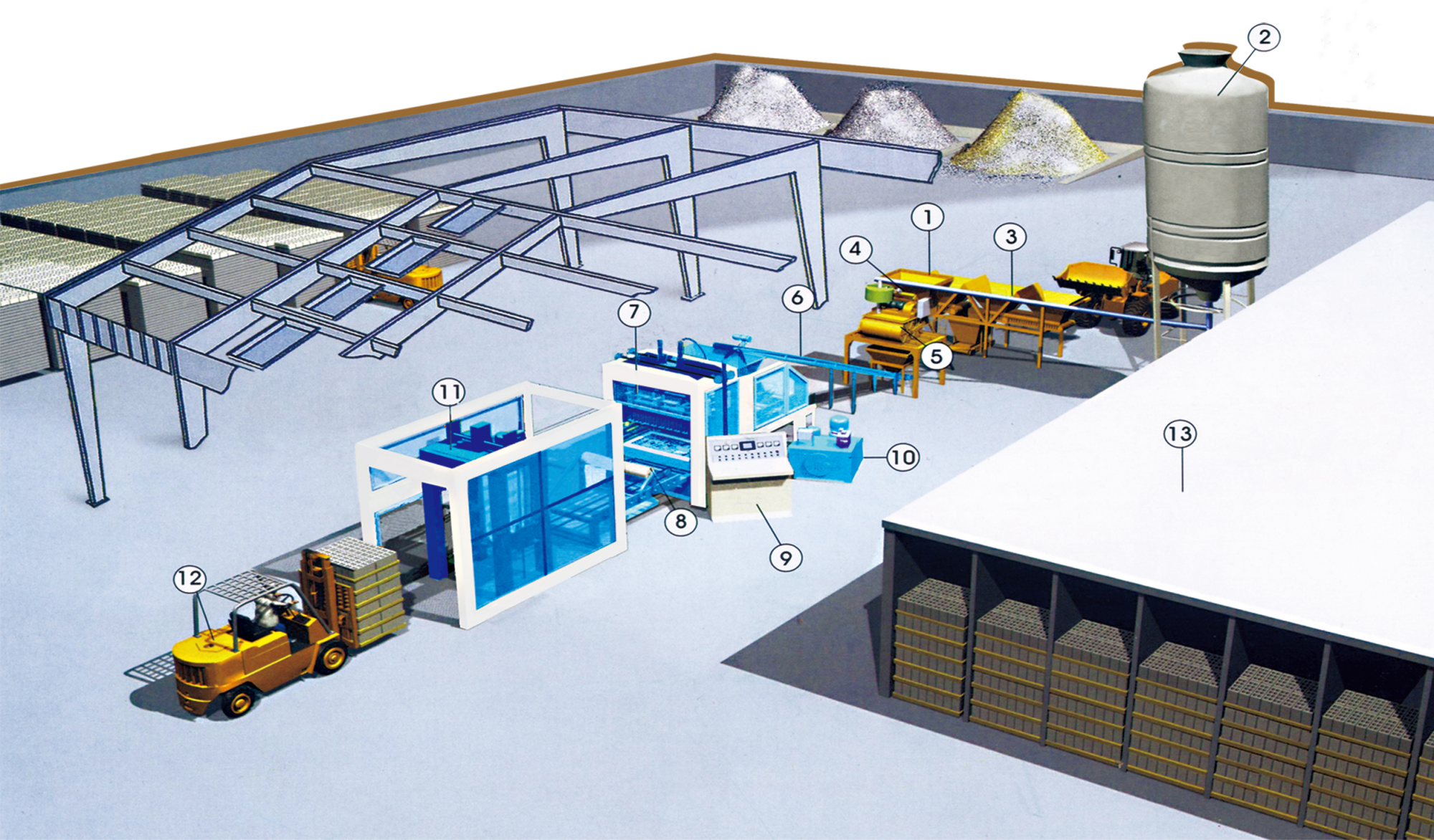

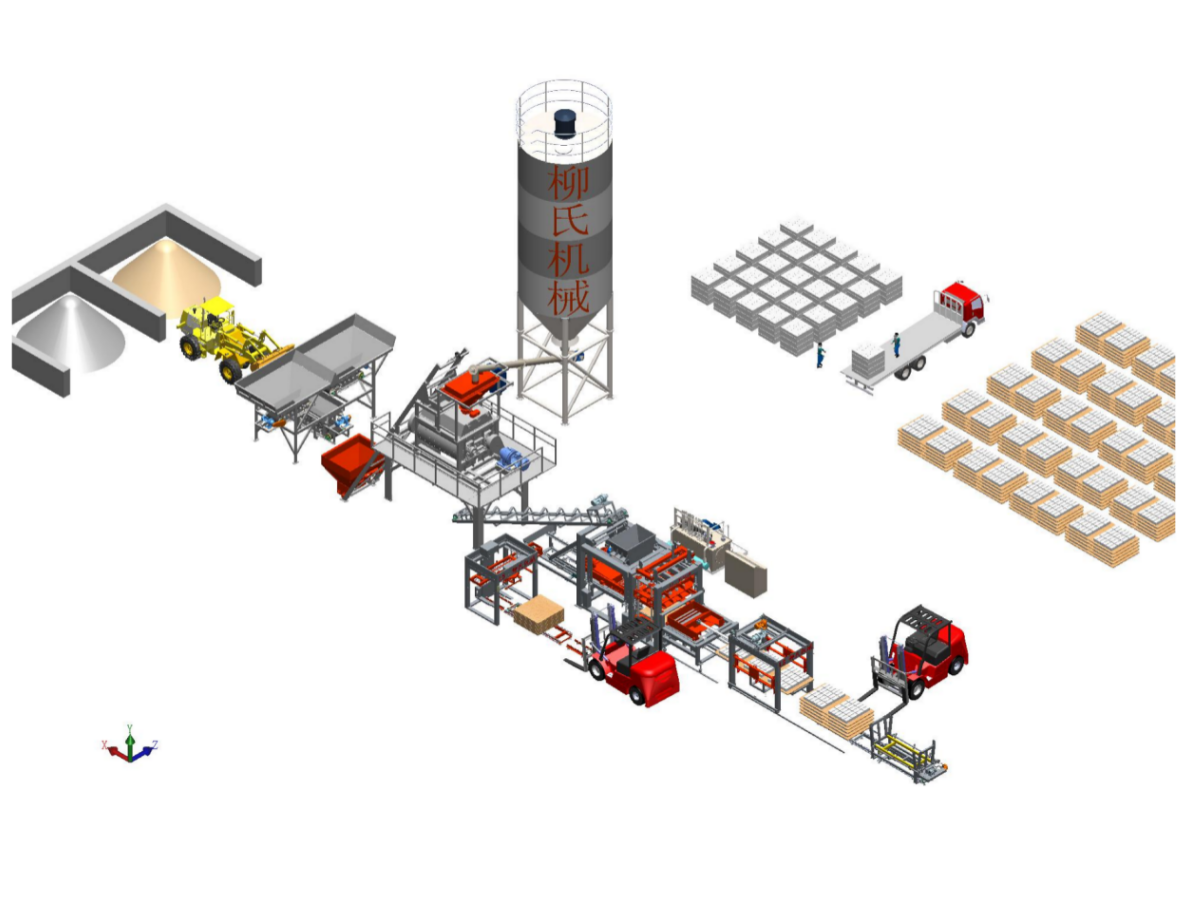

Fully Automatic Brick Making Machine Production Line

LS Fully Automatic Block Production Line

☎ :+86 17750560676

📪:echo@qzlsmachinery.com

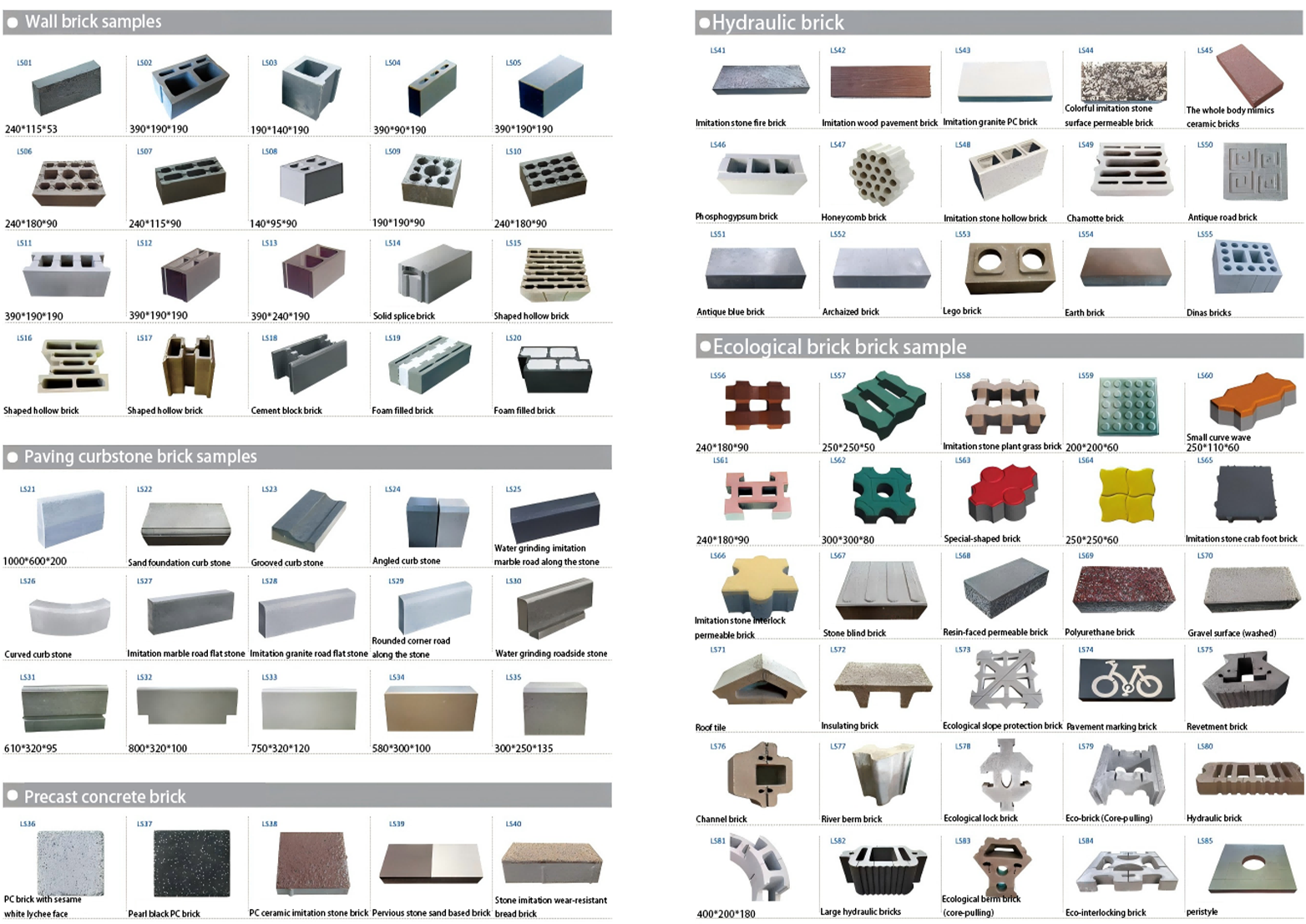

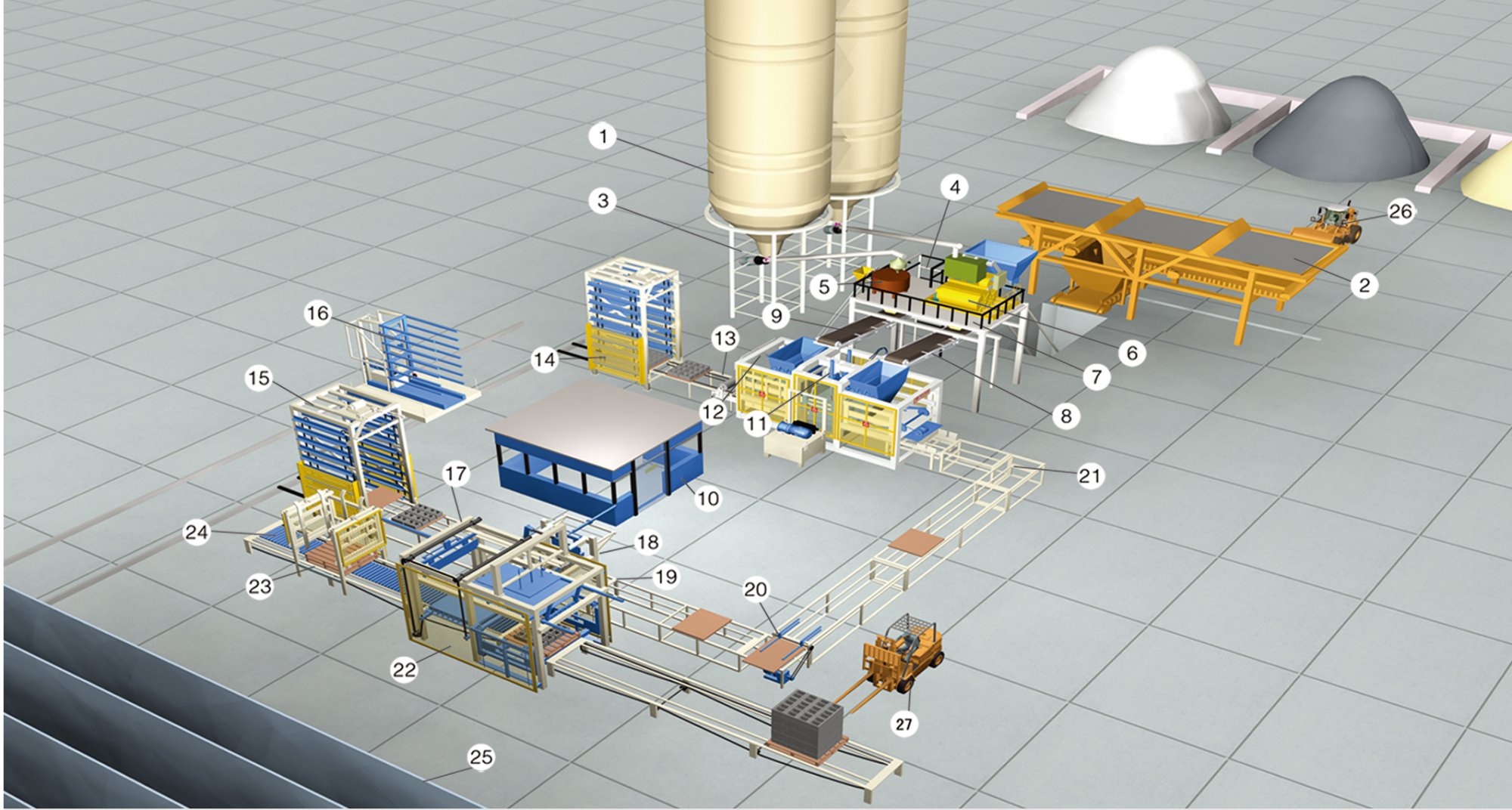

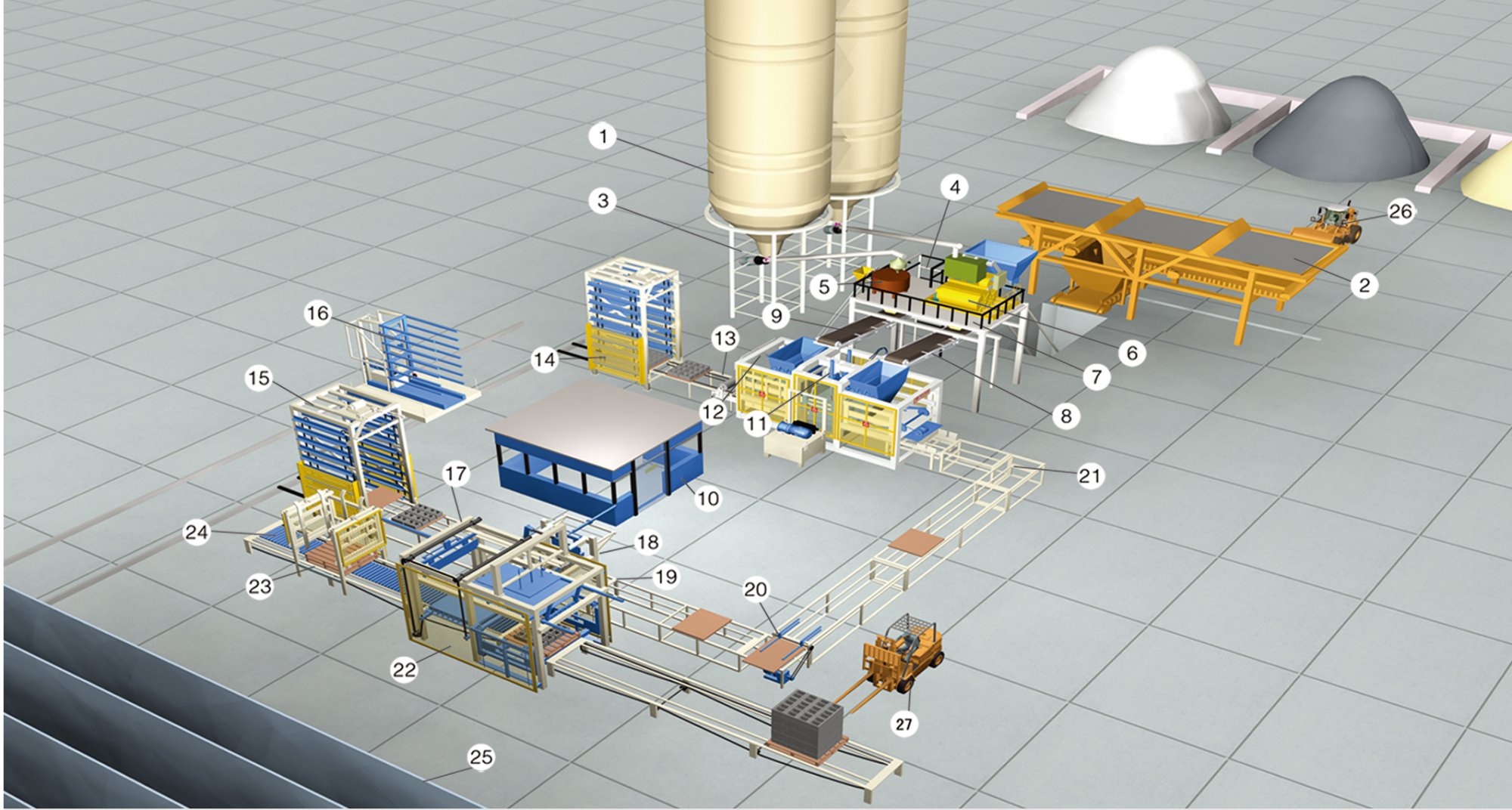

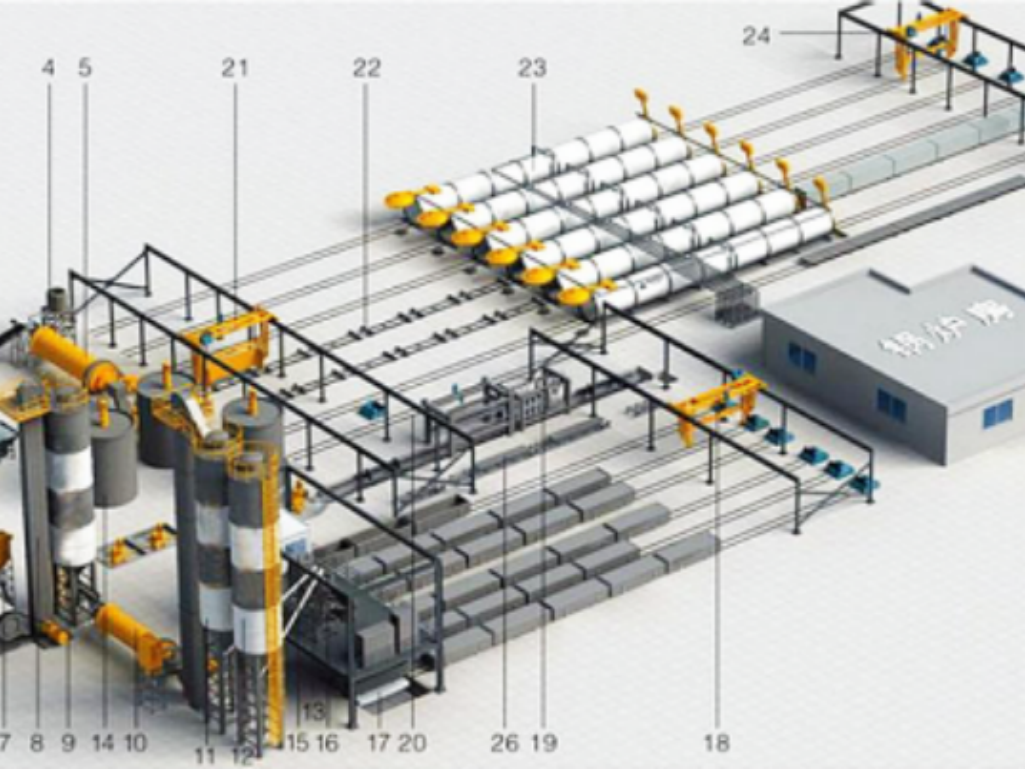

1. Cement Silo The cement silo offers a large storage capacity for cement, ensuring a continuous supply to the production line, reducing downtime, and increasing efficiency.

2. Batcher The batching system ensures precise measurement and mixing of raw materials, providing a consistent and high-quality base for brick production.

3. Screw Conveyor The screw conveyor efficiently transports cement from the silo to the mixer, ensuring a smooth and uninterrupted flow of materials.

4. Cement Scale The cement scale precisely measures the amount of cement needed for each batch, ensuring accurate proportions and high-quality bricks.

5. Plus Materials Mixer The plus materials mixer thoroughly blends additional materials, creating a uniform mixture that enhances the strength and durability of the bricks.

6. Base Materials Mixer The base materials mixer ensures that the primary materials are mixed thoroughly, providing a strong foundation for the brick-making process.

7. Mixing Platform The mixing platform provides a stable and organized area for the mixing process, ensuring efficiency and safety.

8. Base Materials Belt Conveyor The base materials belt conveyor seamlessly transports mixed materials to the block making machine, maintaining a consistent flow and optimizing production efficiency.

9. Plus Materials Belt Conveyor The plus materials belt conveyor ensures additional materials are efficiently transported to the block making machine, enhancing the quality of the final product.

10. Central Control Station The central control station offers precise control over the entire production process, ensuring optimal performance, reducing manual intervention, and increasing overall efficiency.

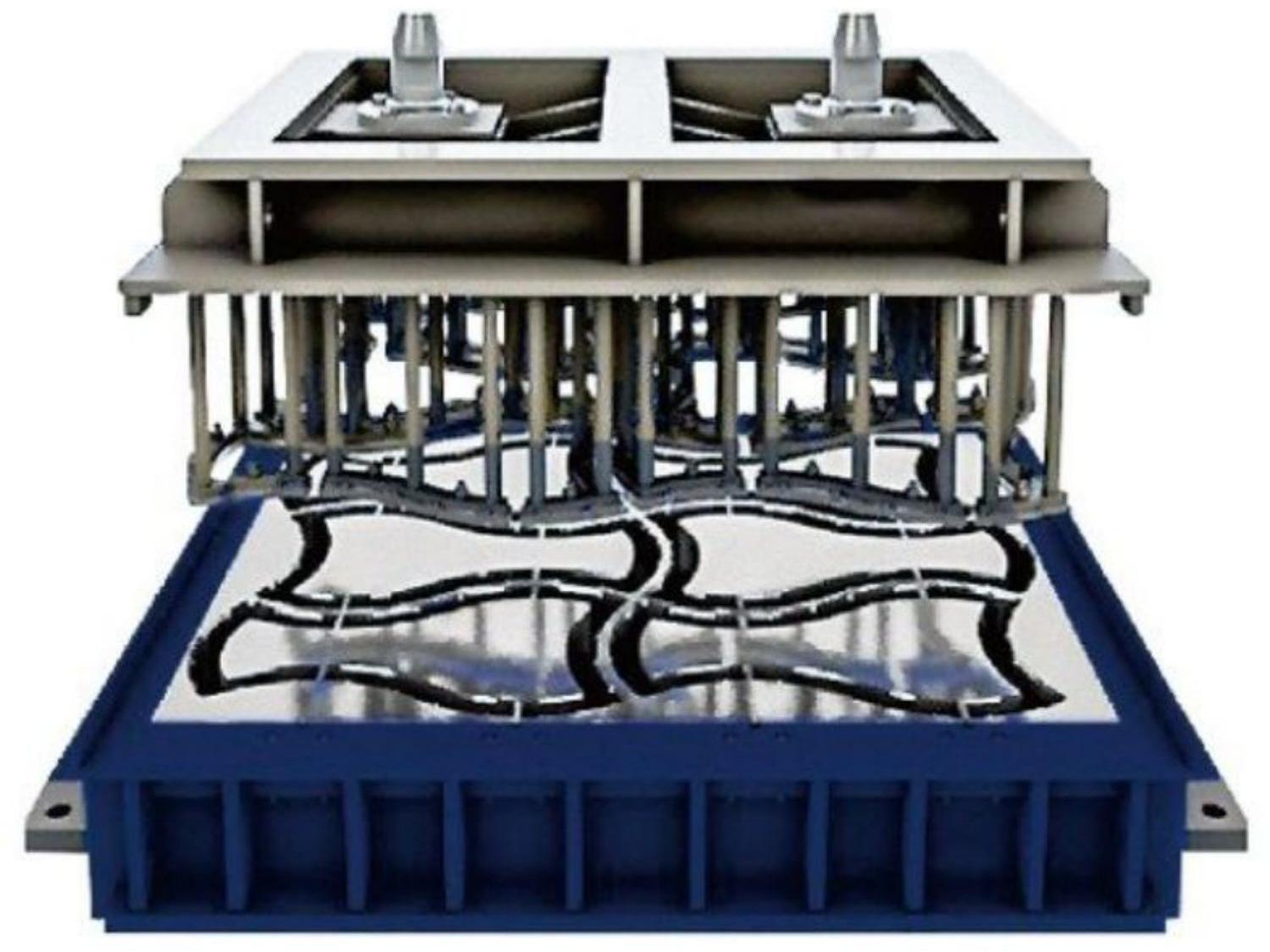

11. Block Making Machine The core of the production line, the block making machine, forms bricks with precision and consistency. It is designed to produce various types of bricks, including PC imitation stone bricks, permeable bricks, and curb stones.

12. Plus Materials Feeding Machine The plus materials feeding machine ensures that additional materials are fed into the block making machine efficiently, enhancing the quality and strength of the bricks.

13. Wet Block Transportation Line The wet block transportation line ensures that freshly made bricks are transported carefully to avoid damage, maintaining their quality.

14. Ascending Machine The ascending machine efficiently lifts blocks to the next stage of the production process, optimizing the flow and reducing manual labor.

15. Descending Machine The descending machine lowers blocks to the appropriate level for further processing, ensuring a smooth and efficient workflow.

16. Finger Cart The finger cart efficiently transports bricks between different stages of the production process, reducing manual handling and increasing productivity.

17. Dry Block Transportation Line The dry block transportation line ensures that cured bricks are transported carefully to avoid damage, maintaining their quality.

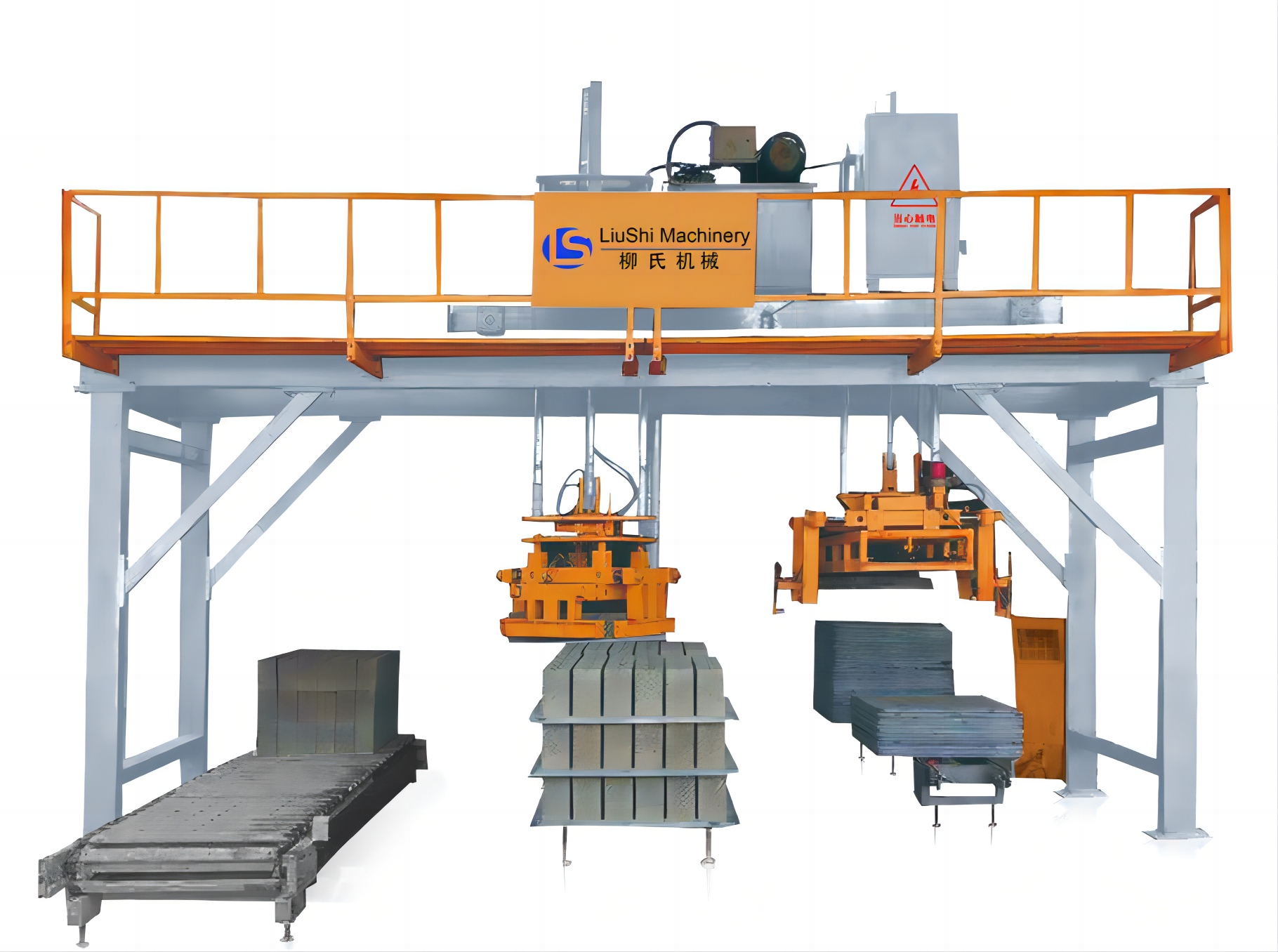

18. Depiler The depiler efficiently separates and organizes cured bricks, readying them for packaging or further processing.

19. Horizontal Pallets Feeder The horizontal pallets feeder ensures that pallets are fed into the production line efficiently, reducing manual labor and optimizing productivity.

20. Pallets Turnover Machine The pallets turnover machine efficiently flips pallets, ensuring that bricks are processed evenly and consistently.

21. Pallet Feeder The pallet feeder ensures that pallets are fed into the block making machine efficiently, reducing manual labor and optimizing productivity.

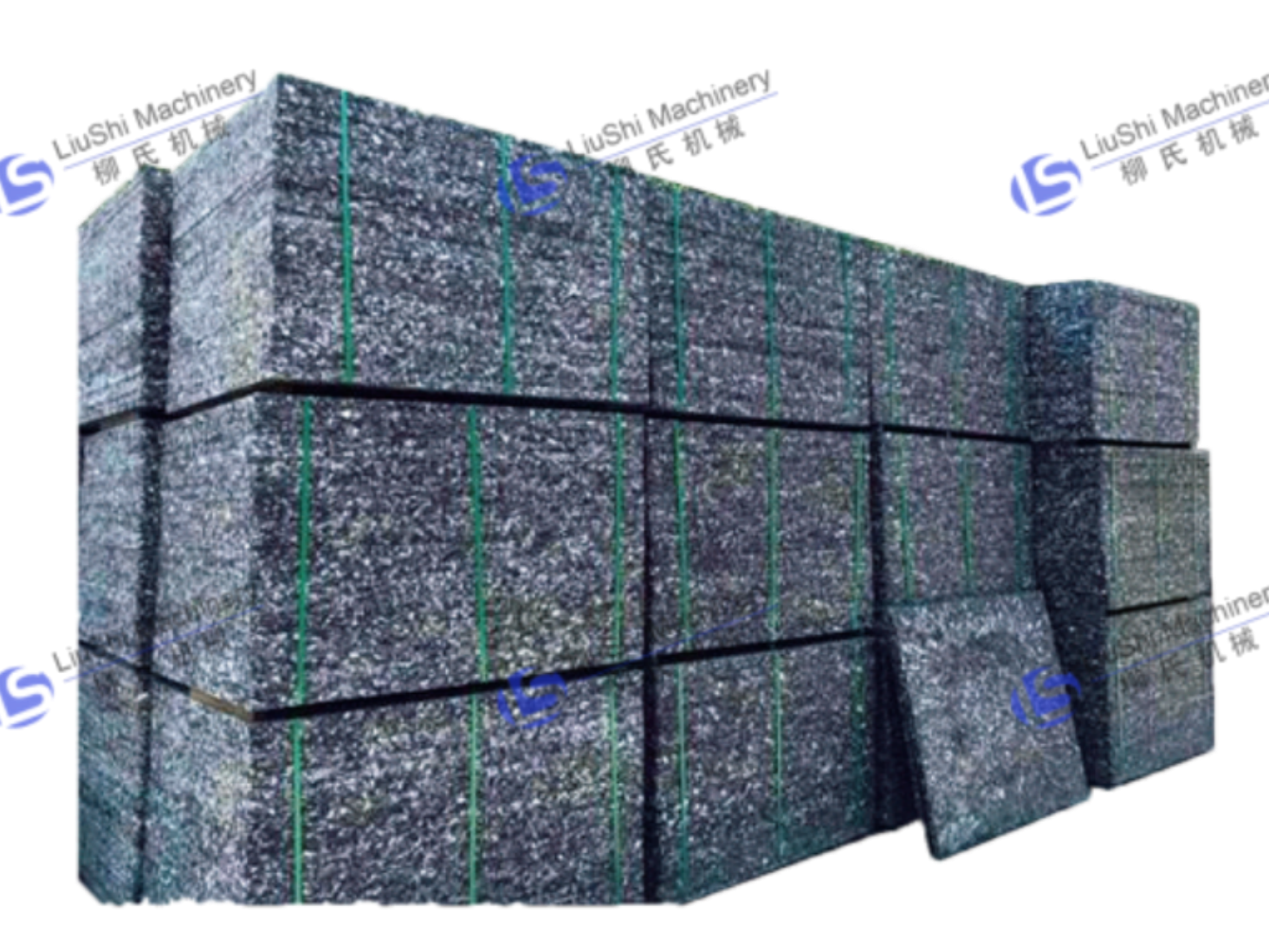

22. Cuber The cuber neatly stacks finished bricks, readying them for transportation or storage, reducing manual labor and improving productivity.

23. Pallets Storehouse The pallets storehouse provides organized and efficient storage for pallets, ensuring they are readily available for use in the production process.

24. Cuber Railway The cuber railway ensures that stacked bricks are transported efficiently to the storage area, reducing manual handling and increasing productivity.

25. Curing Kiln The curing kiln provides a controlled environment for bricks to cure, ensuring they achieve the desired strength and durability.

26. Wheeled Loader The wheeled loader is used to transport raw materials and finished bricks, facilitating easy and efficient handling.

27. Forklift The forklift is used to transport stacked bricks to the curing room or storage area, facilitating easy and efficient handling.

Company Information

Quanzhou Liushi Machinery Co., Ltd., established in 2006, is a modern technology company specializing in the research, development, manufacturing, sales, and service of brick-making machinery. Our strong R&D team has earned the company recognition as a high-tech enterprise and holds numerous independent research and development patents. In the era of Industry 4.0, we rely on the "Internet+" concept to continuously strengthen the idea of "Technology Strengthens the Enterprise," reaching advanced industry levels.

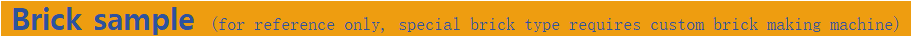

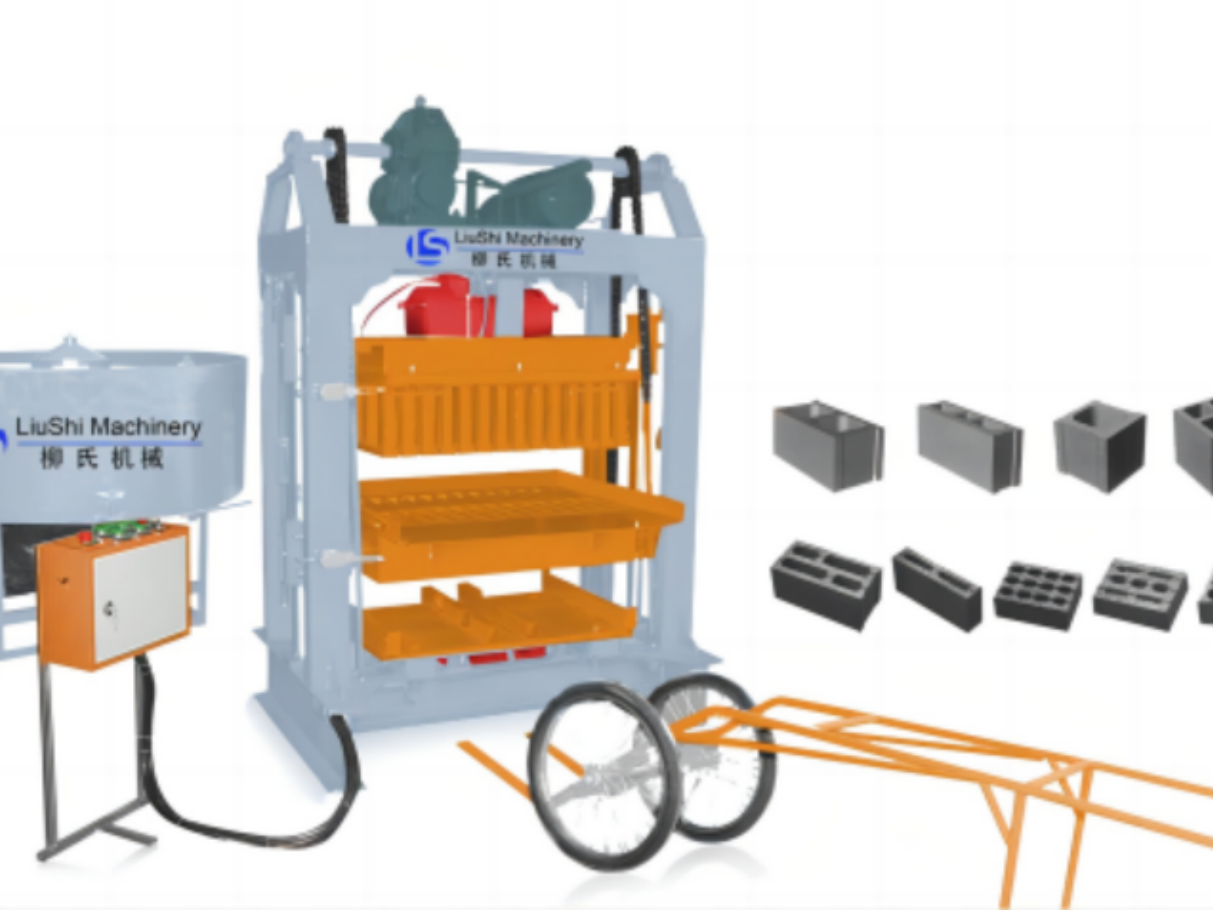

Our comprehensive production system produces the "LS" series of non-fired brick machines (cement brick machines), including fully automatic forming brick machines, pallet-free brick machines, and hydraulic brick machines. These machines boast high automation, stable quality, strong durability, and high production efficiency.

Customized according to user needs, we specialize in producing non-fired cement brick machines, including static pressure brick machines, pallet-free brick machines, fully automatic block forming machines, brick stacker packing machines, and cement brick curing kiln production lines. These machines are suitable for producing various specifications of colored pavement bricks, interlocking blocks, grass bricks, ecological slope protection bricks, imitation stone curbstones, imitation stone PC bricks, and clean water wall bricks.

With a factory area of over 10,000 square meters, our products are sold domestically and internationally. We have been awarded over 50 patents and employ more than 100 staff members. Choose Quanzhou Liushi Machinery Co., Ltd. for high-quality, efficient brick-making equipment and professional after-sales service, providing a solid foundation for the growth of your business.

Fully Automatic Block Making Machine

Fully Automatic Block Making Machine Fully Automatic Brick Making Machine Production Line

Fully Automatic Brick Making Machine Production Line AAC Brick Making Machine Production Line

AAC Brick Making Machine Production Line Small Brick Making Machine

Small Brick Making Machine Palletizing System

Palletizing System Concrete Mixer

Concrete Mixer Block Mould

Block Mould Brick Machine Supporting Equipment

Brick Machine Supporting Equipment