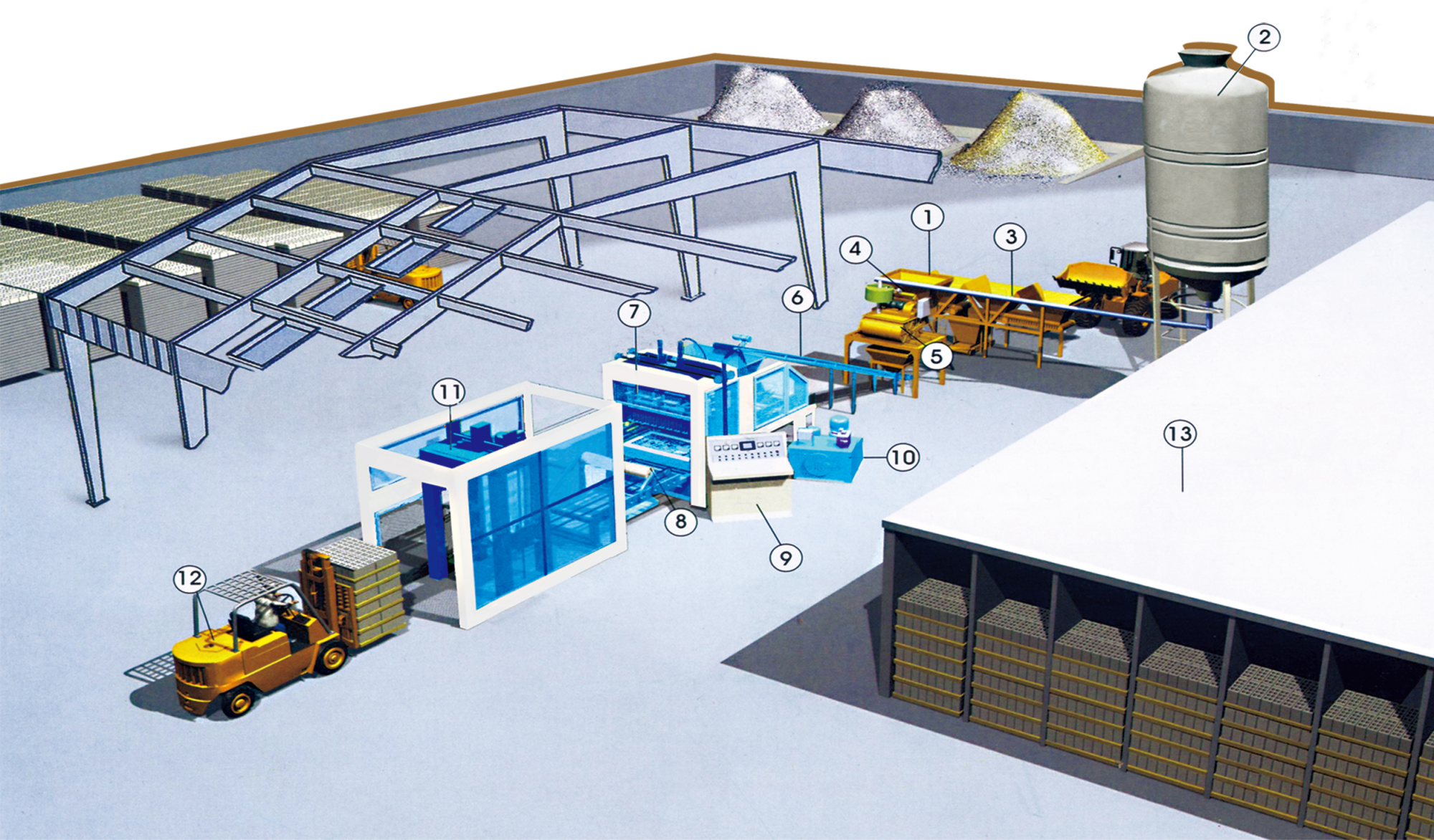

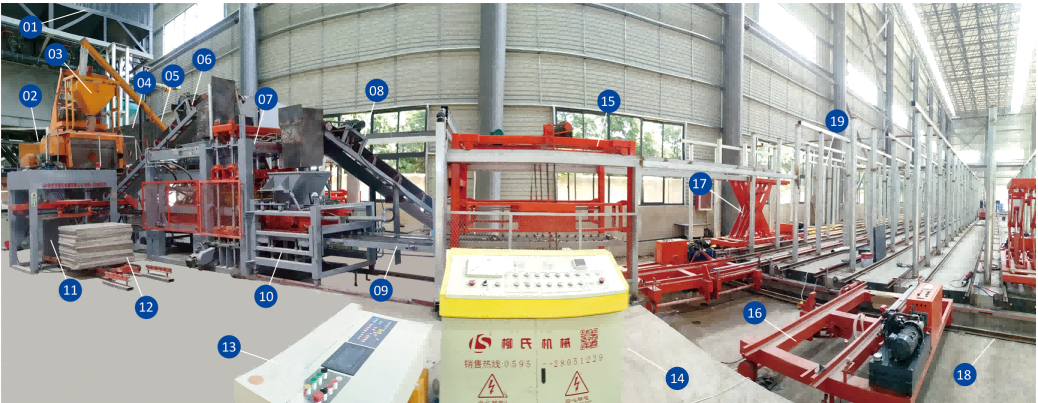

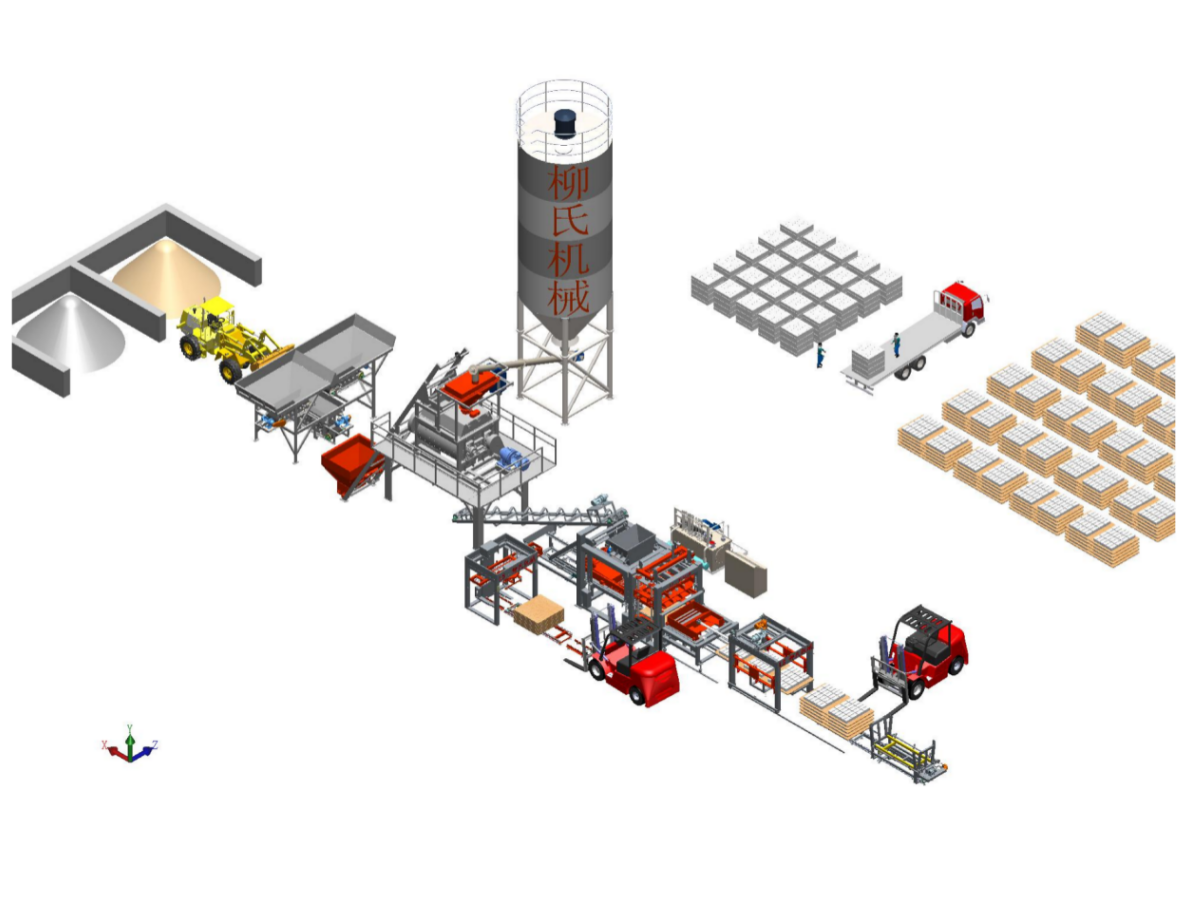

Fully Automatic Brick Making Machine Production Line

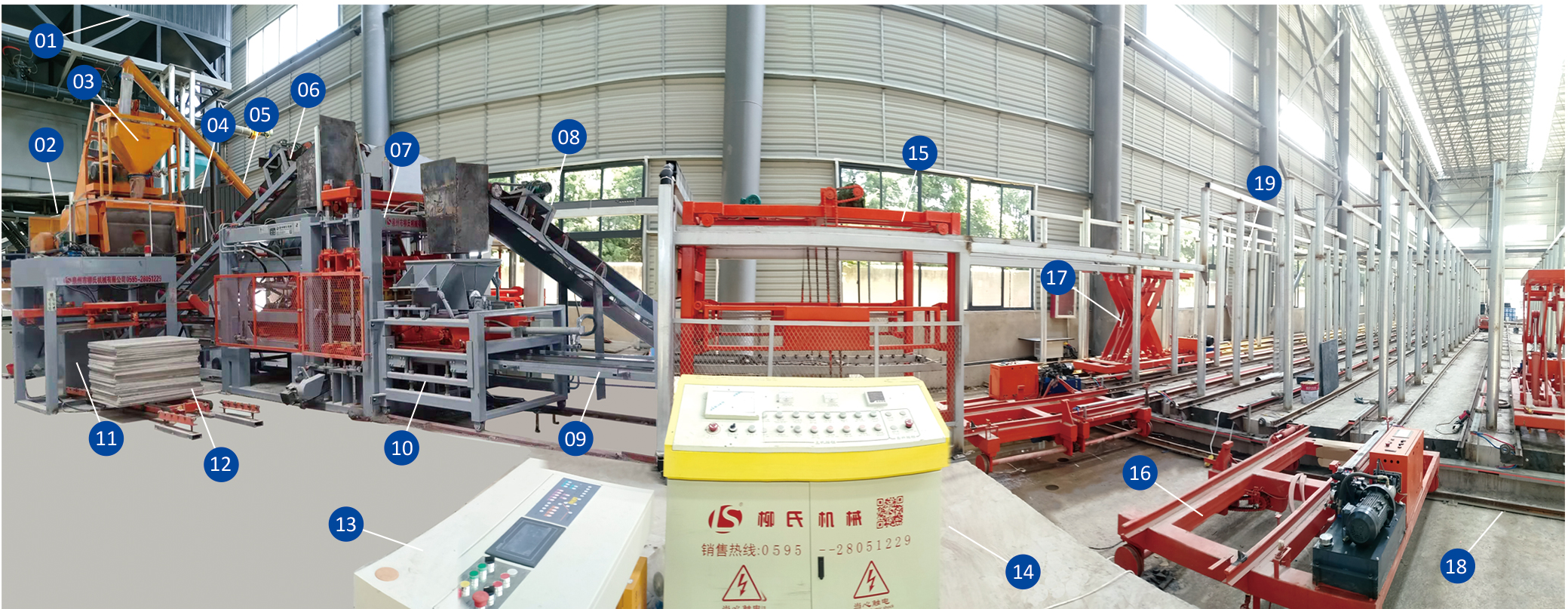

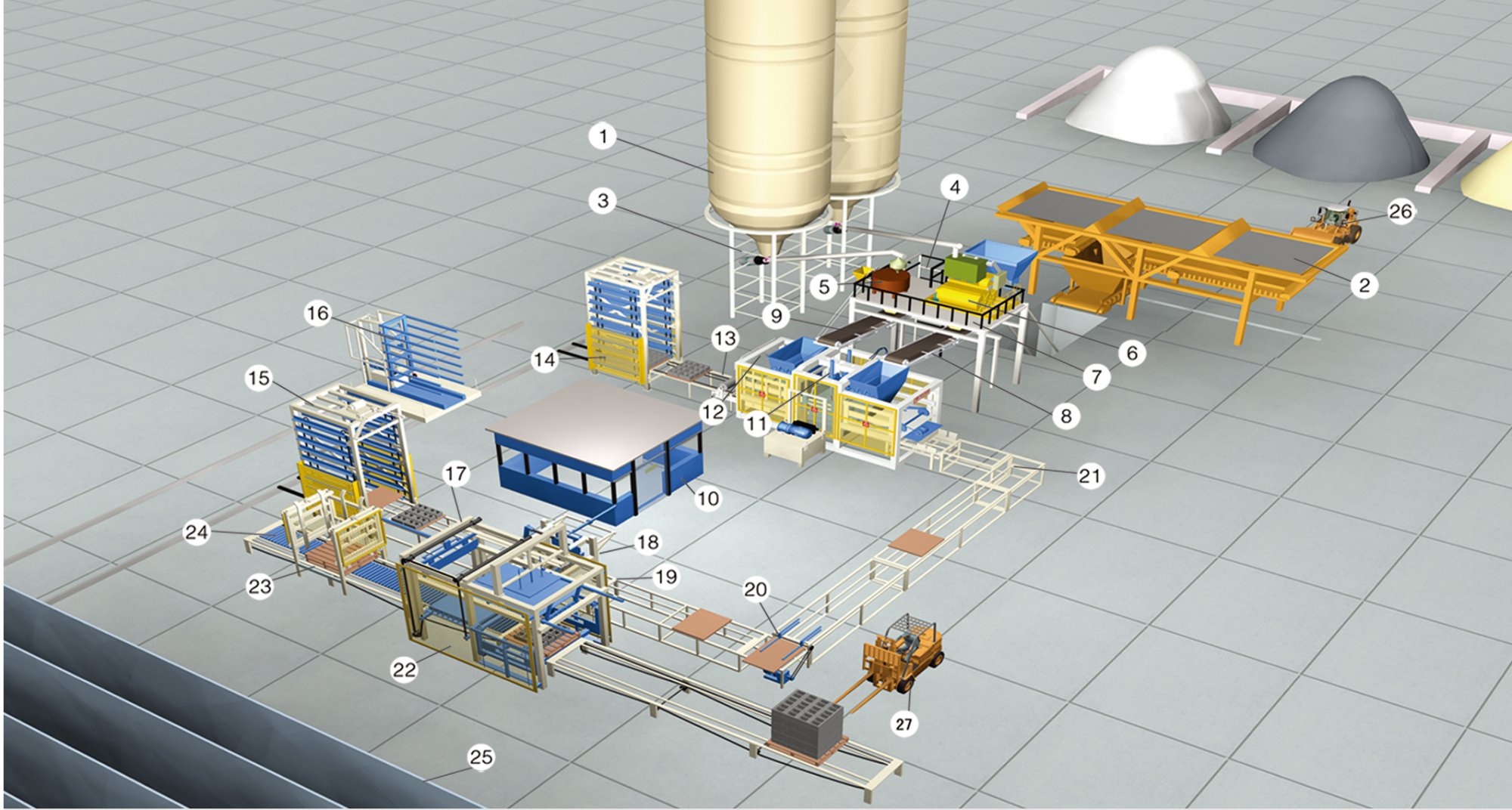

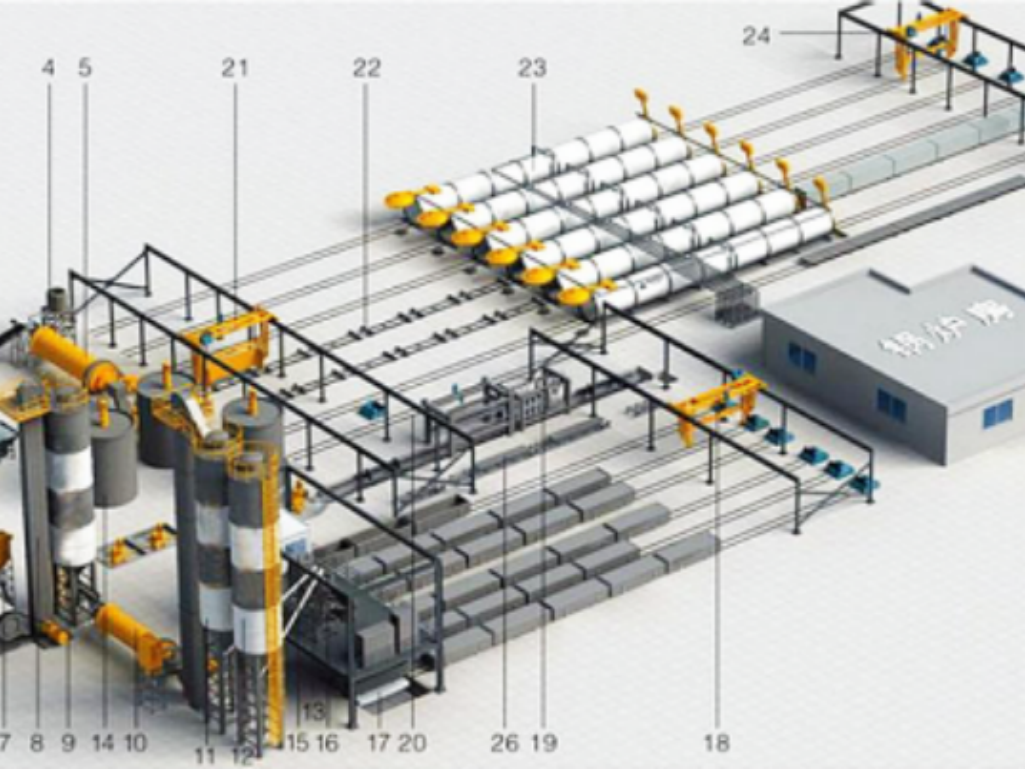

RGV Intelligent Shuttle Car Maintenance Kiln Fully Automatic Production Line

Cement Silo ( 01):

- Large capacity for storing cement, ensuring a continuous supply to the production line.

- Equipped with dust removal and level sensing devices for optimal operation and maintenance.

Base Material Mixer ( 02):

- High-efficiency mixing to ensure uniform base material composition.

- Robust construction for long-lasting performance.

Cement Scale (03):

- Precise weighing system to maintain accurate cement ratios in the mix.

- Integrated with the control system for seamless operation.

Batcher (04):

- Automated batching of raw materials for consistent quality.

- Adjustable settings to accommodate various material types and proportions.

Screw Conveyor (05):

- Efficiently transports cement and other materials to the mixer.

- Designed to minimize material spillage and dust generation.

Base Materials Belt Conveyor (06):

- Durable and reliable conveyor system for moving base materials.

- Optimized for smooth and continuous operation.

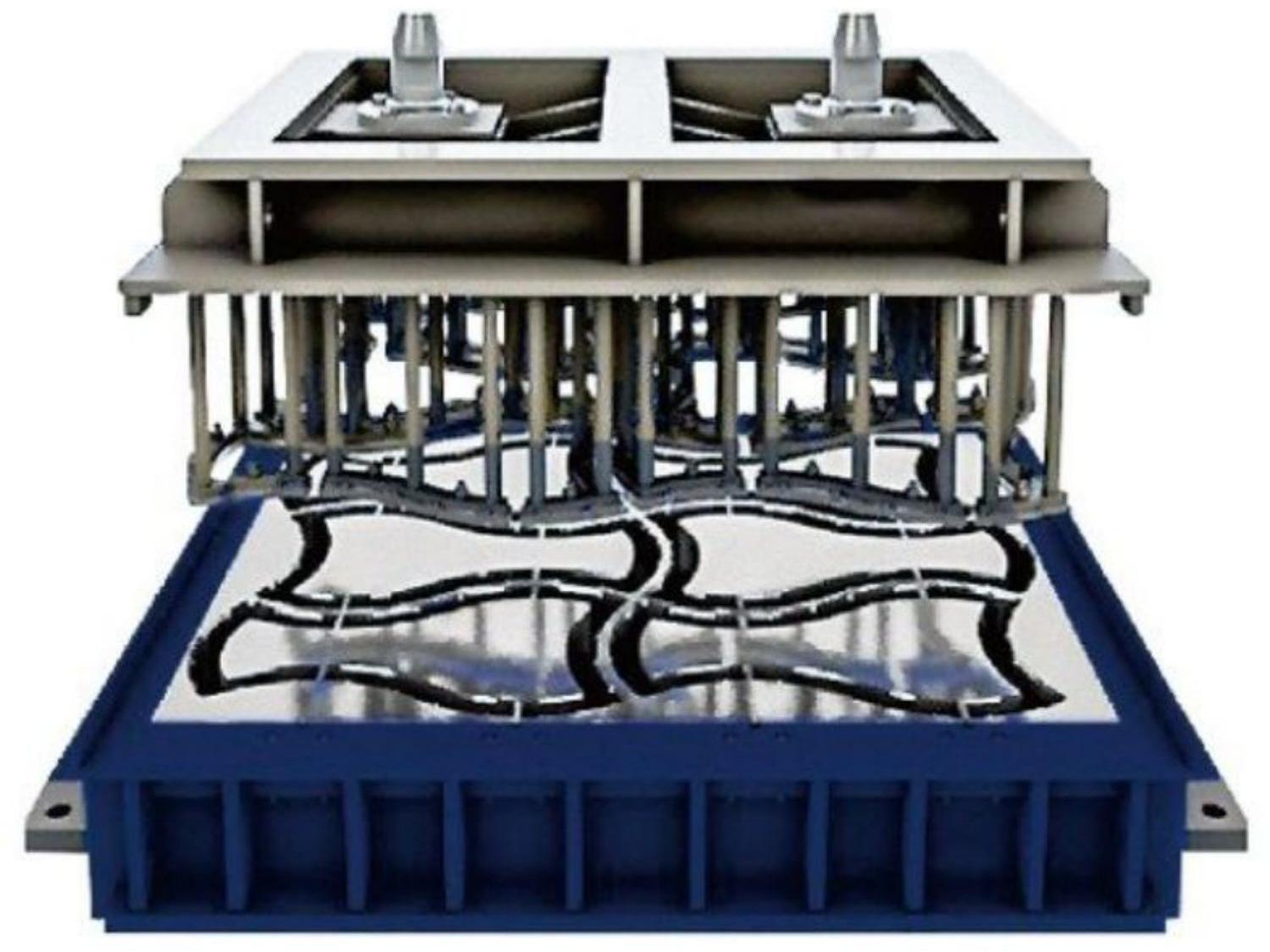

Host Forming Machine (07):

- Core component for brick forming, featuring high precision and stability.

- Capable of producing various brick types and sizes.

Base Belt Conveyor (08):

- Ensures consistent feeding of materials to the forming machine.

- Constructed for high wear resistance and durability.

Wet Block Conveyor (09):

- Transfers freshly formed wet bricks to the next stage with minimal damage.

- Designed to handle large volumes efficiently.

Plus Materials Feeding Machine (10):

- Adds additional materials or layers to bricks as required.

- Enhances the versatility and customization of brick products.

- Pallet Feeding Machine (11):

- Automated system for feeding pallets into the production line.

- Increases efficiency and reduces manual labor.

- Block Pallets (12):

- High-quality pallets designed for repeated use.

- Ensures stability and uniformity in brick stacking and curing.

- RGV Finger Cart System (13):

- Advanced control system for the RGV shuttle cars.

- Ensures precise and coordinated movements throughout the production process.

- Host Operation Control System (14):

- Centralized control system for overseeing the entire production line.

- User-friendly interface for easy operation and monitoring.

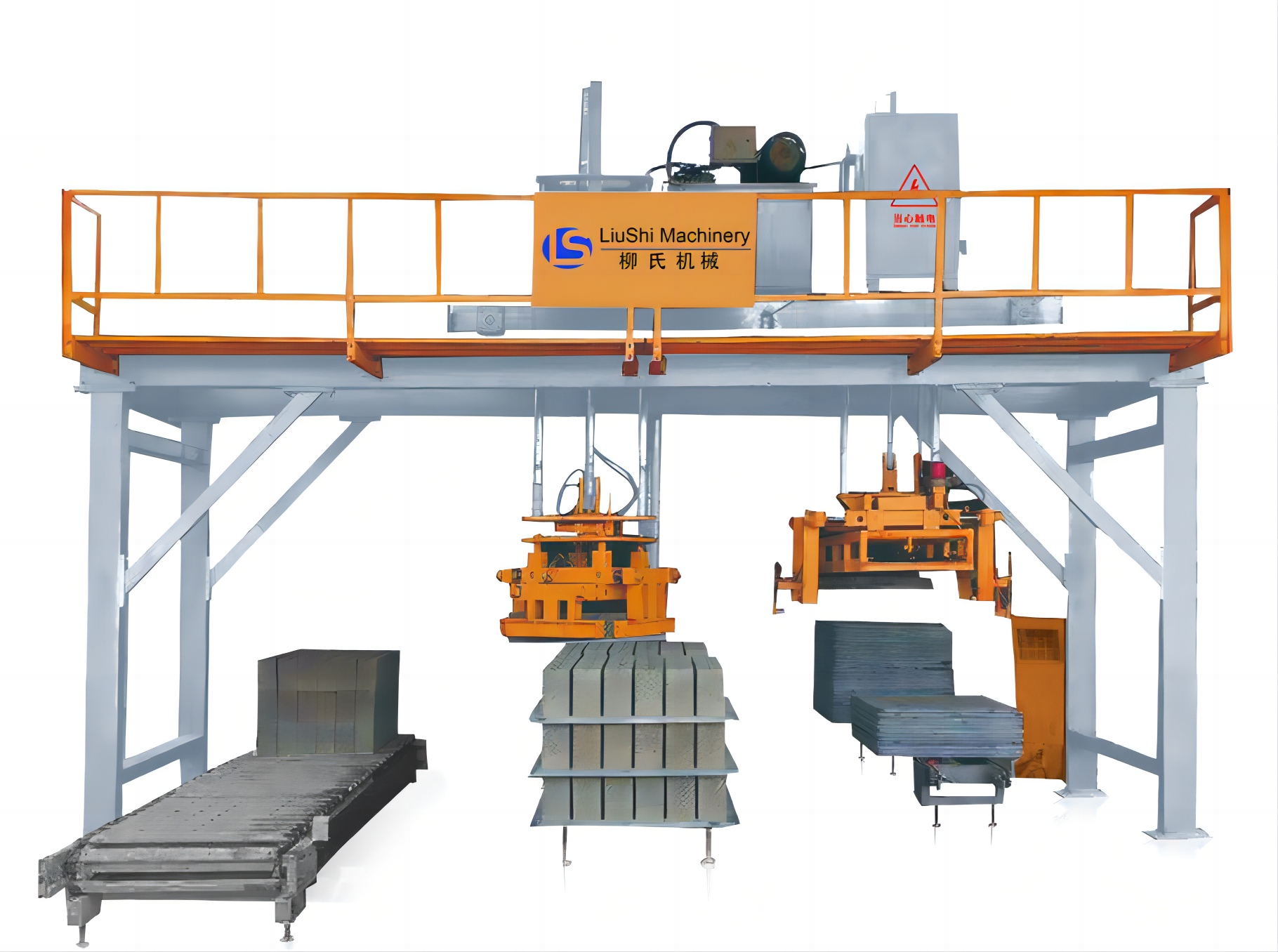

- Ascending/Descending Palletizing System (15):

- Automated system for stacking and unstacking pallets.

- Enhances production speed and efficiency.

- RGV Parent Vehicle (16):

- Main vehicle for transporting materials and bricks within the production line.

- Equipped with advanced navigation and control systems.

- RGV Sub Vehicle (17):

- Assists the parent vehicle in material transport and handling.

- Designed for precision and reliability.

- Track (18):

- Durable tracks for RGV vehicles, ensuring smooth and efficient movement.

- Engineered for long-term use and minimal maintenance.

- Curing Rack (19):

- Provides optimal conditions for brick curing.

- Constructed to hold large quantities of bricks securely.

Company Advantages

Quanzhou Liushi Machinery Co., Ltd, established in 2006, is a modern technical enterprise specializing in the research, development, manufacturing, sales, and service of brick-making machinery. Our strong R&D team has obtained numerous high-tech enterprise certifications and independent research patents. Leveraging the "Internet+" approach in the era of Industry 4.0, we continuously strengthen our "technology-driven enterprise" philosophy, achieving advanced industry standards.

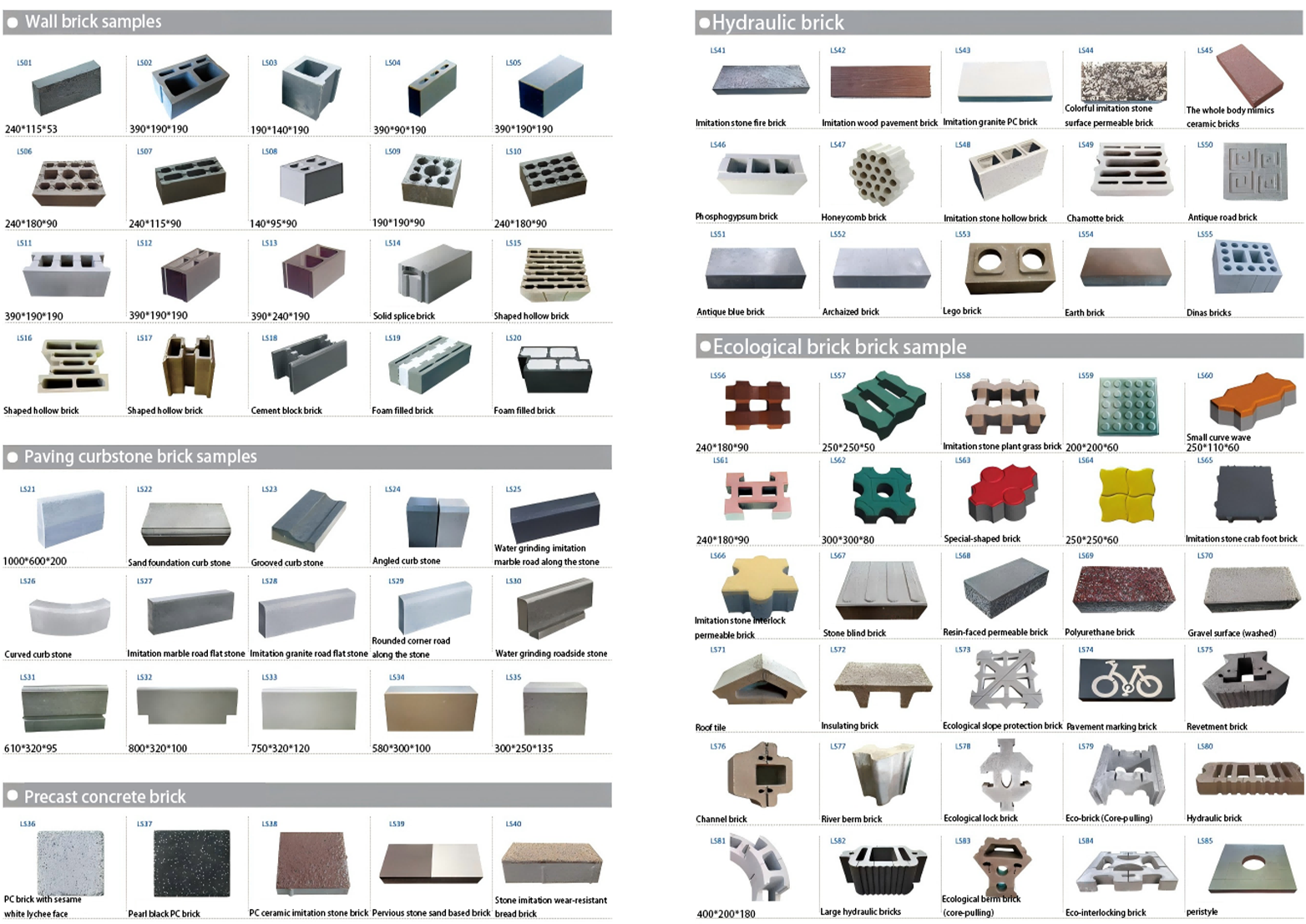

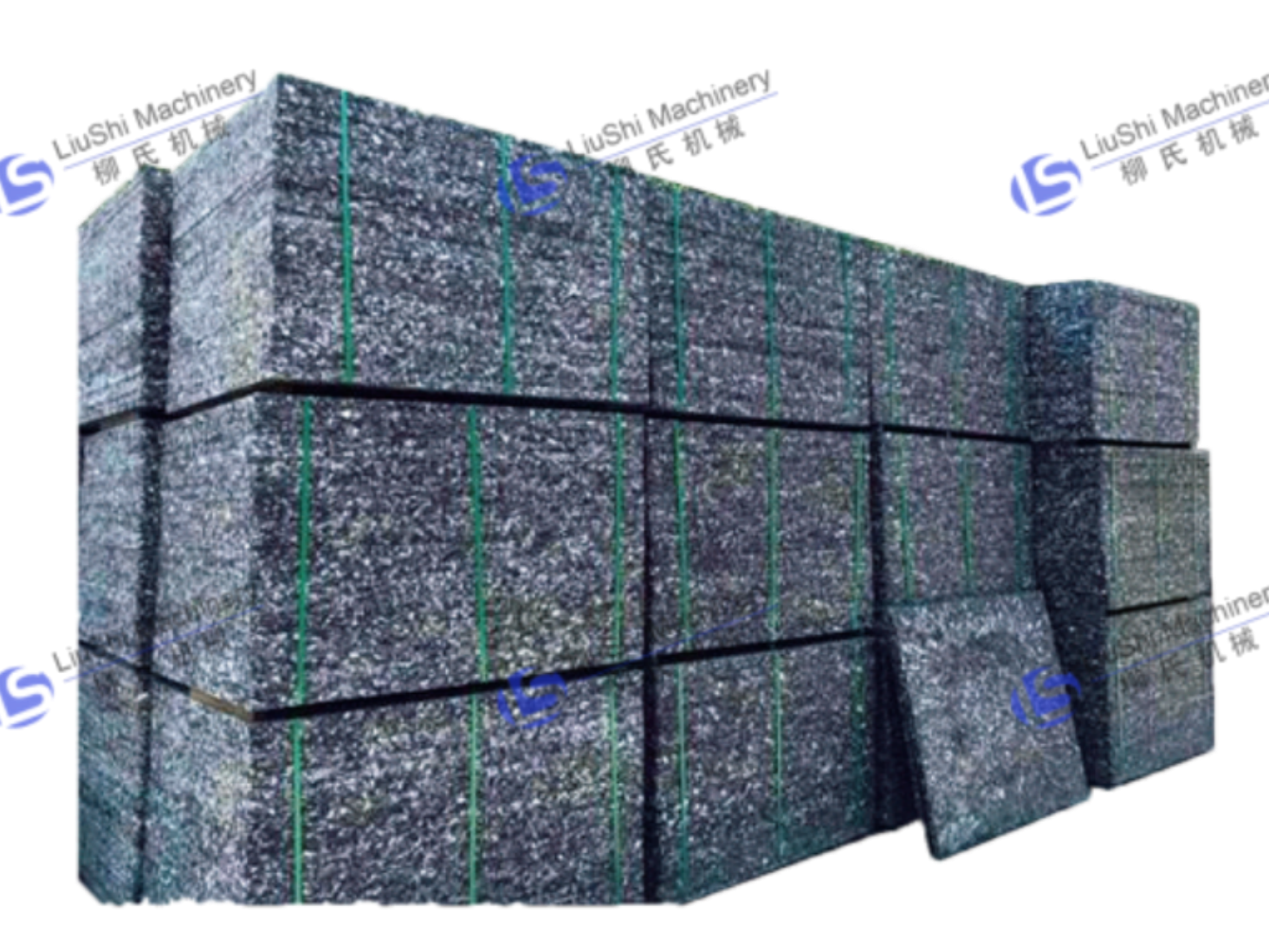

Comprehensive Production System

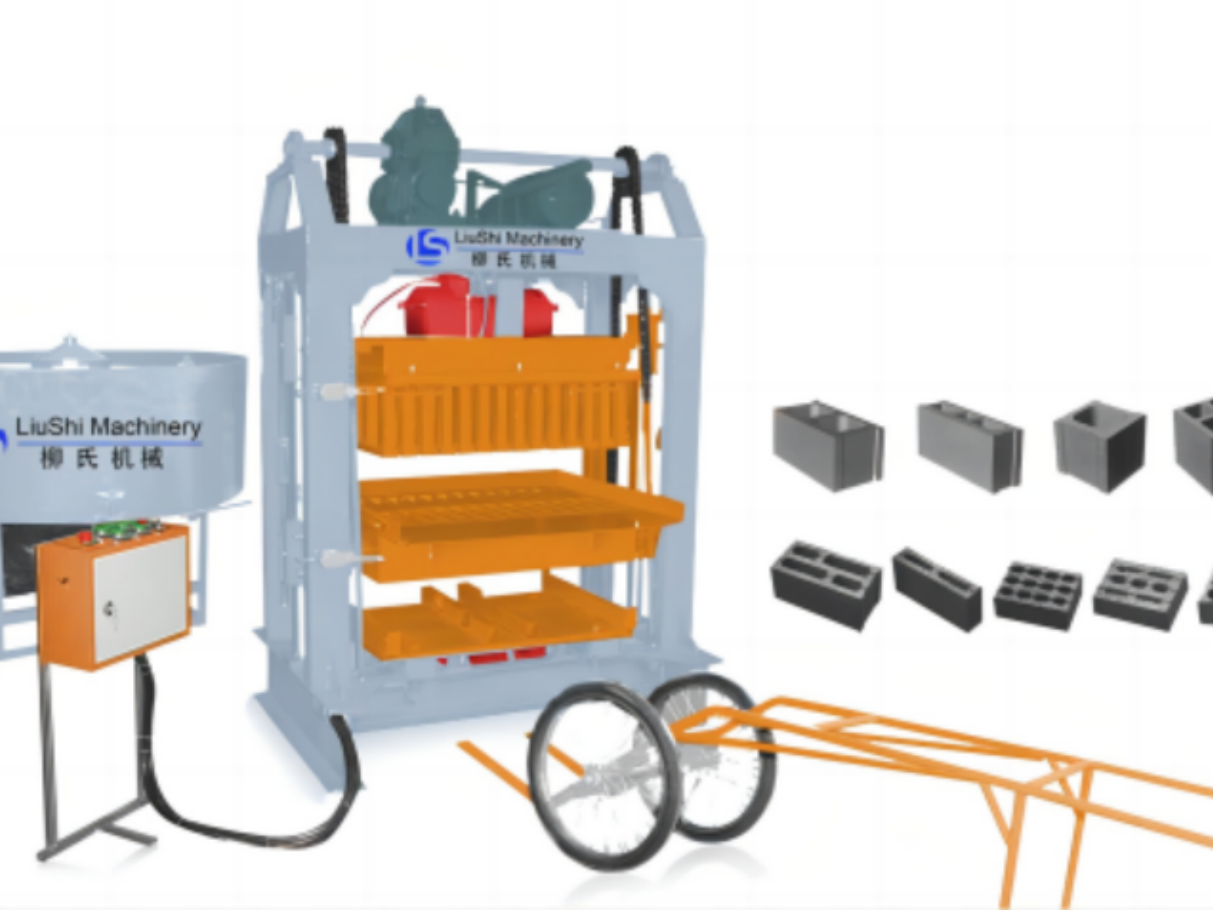

Our production system includes the "LS" series of non-burn brick machines (cement brick machines), featuring high automation, stable quality, durability, and high production efficiency. We offer customization based on user requirements, producing non-burn cement brick machines, static pressure brick machines, non-pallet brick machines, fully automatic block forming machines, brick stacking machines, packaging machines, cement brick curing kiln rings, and other machinery. Our equipment is suitable for producing various types of building bricks, including colorful pavement bricks, interlocking blocks, grass bricks, ecological slope protection bricks, imitation stone curbs, and PC bricks.

Contact Us

For more information about our products or to discuss business opportunities, please feel free to contact us.

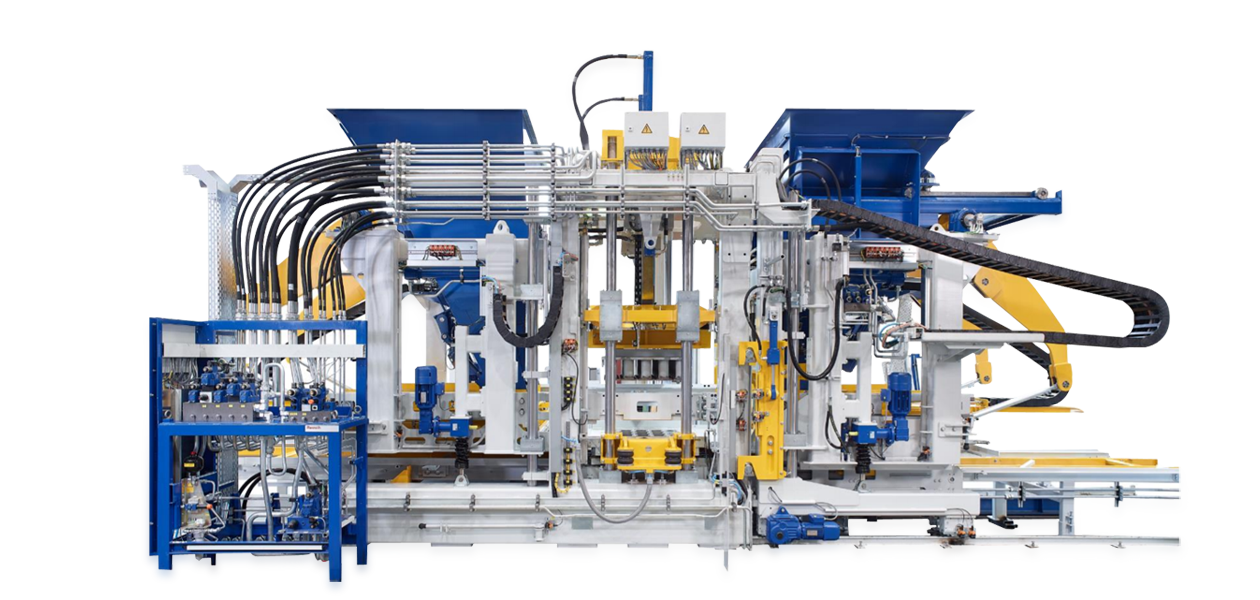

Fully Automatic Block Making Machine

Fully Automatic Block Making Machine Fully Automatic Brick Making Machine Production Line

Fully Automatic Brick Making Machine Production Line AAC Brick Making Machine Production Line

AAC Brick Making Machine Production Line Small Brick Making Machine

Small Brick Making Machine Palletizing System

Palletizing System Concrete Mixer

Concrete Mixer Block Mould

Block Mould Brick Machine Supporting Equipment

Brick Machine Supporting Equipment